For distributors, wholesalers, and EPC contractors in the renewable energy sector, accurately forecasting the Total Landed Cost of an Energy Storage System (BESS) is paramount. While the Ex-Works (EXW) price forms the baseline, two highly volatile and complex factors can drastically alter the final project budget: logistics costs and tariffs. A failure to precisely calculate and manage these variables can lead to margin erosion, project delays, and loss of competitive advantage.

Table of Contents

ToggleThis in-depth analysis will provide a professional-grade examination of how global logistics costs and import tariffs directly impact the final energy storage system price. We will dissect cost structures, clarify critical trade terminology, and provide strategies rooted in real-world operational experience to help you navigate this complex landscape.

Authored by the Xiensolar Market Intelligence Team.

This analysis is part of our ongoing “Global BESS Supply Chain Intelligence” series. As a leading provider of energy storage solutions, we manage hundreds of international shipments annually, navigating the complex interplay of logistics, customs, and regulatory landscapes. This article synthesizes our first-hand operational data, insights from our network of freight forwarders and customs brokers, and our analysis of market trends as of Q3 2025. Our goal is to move beyond surface-level discussion and provide distributors and EPC contractors with the granular, actionable intelligence needed to protect project profitability.

The Global BESS Supply Chain: Logistics Models and Trade Terms

The journey of a BESS from factory to project site is governed by a framework of international standards and agreements. Understanding this framework is the first step toward cost control.

Common Transportation Methods:

Sea Freight: The overwhelming choice for BESS transportation, offering the lowest cost per unit of weight/volume. It is ideal for non-urgent, high-volume shipments using 20ft or 40ft Full Container Loads (FCL).

Rail Freight: A strategic alternative for Eurasia trade lanes, offering a balance between the speed of air freight and the cost of sea freight.

Multimodal Transport: The standard for door-to-door delivery, combining sea or rail with final-mile trucking to the project site.

Decoding International Commercial Terms (Incoterms):

The choice of Incoterm is a critical contractual decision that defines the division of costs, risks, and responsibilities between the seller (manufacturer) and the buyer (you). Misunderstanding these terms can lead to unexpected costs.

EXW (Ex Works): The seller’s only responsibility is to make the goods available at their factory. The buyer bears all costs and risks from that point onward, including loading, export clearance, main freight, and import duties. While it may offer the lowest initial unit price, EXW places the maximum logistical burden on the buyer.

FOB (Free On Board): The seller is responsible for all costs and risks until the goods are loaded on board the vessel nominated by the buyer at the named port of shipment. The buyer then assumes responsibility for the main sea freight, insurance, and all subsequent costs. This is a very common and balanced term.

CIF (Cost, Insurance, and Freight): The seller arranges and pays for the main carriage (sea freight) and minimum insurance coverage to the named destination port. However, risk transfers from seller to buyer once the goods are on board the vessel. It’s crucial to note that the buyer is still responsible for import customs clearance and any duties/taxes. Many countries, including the United States, use the CIF value as the basis for calculating import tariffs.

Global Logistics Cost Volatility: Drivers and First-Hand Experience

The freight rate trend is notoriously volatile. A purely theoretical understanding is insufficient; real-world events constantly reshape the cost landscape.

Key Cost Components & Their Drivers:

Ocean Freight Rates: These are the base rates for container transport. According to major freight indices like the Freightos Baltic Index (FBX), rates that spiked post-pandemic have seen renewed volatility due to geopolitical events.

Surcharges (BAF, PSS, etc.): These are variable costs added by carriers. The Bunker Adjustment Factor (BAF) is tied to fuel prices, while Peak Season Surcharges (PSS) can be applied during high-demand periods.

Terminal Handling Charges (THC): Fees charged by the port for handling containers.

Real-World Experience: Navigating the Red Sea Crisis “In Q1 2025, we managed a critical BESS shipment for a European data center project. The vessel was rerouted from the Suez Canal around the Cape of Good Hope due to the Red Sea crisis. The initial 35-day transit plan extended to nearly 50 days. More critically, the carrier imposed an emergency ‘Contingency Surcharge’ of $1,500 per container. This experience reinforces a core principle: always build a 3-4 week time buffer and a 5-10% cost contingency into any project plan relying on international sea freight.”

Tariffs are a non-negotiable government levy. Their accurate calculation hinges on a precise understanding of customs regulations.

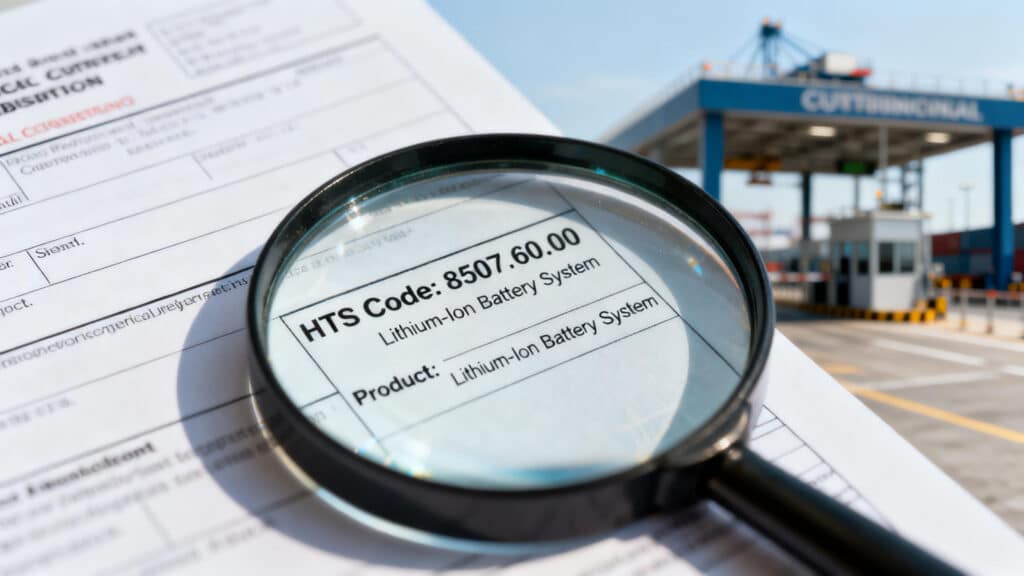

The Basis of Tariff Classification: The Harmonized Tariff Schedule (HTS)

The exact duty rate applied to a BESS is determined by its classification under the Harmonized Tariff Schedule (HTS), a globally standardized system of names and numbers to classify traded products.

Example HTS Codes for BESS:

8507.60.00: Lithium-ion batteries (including packs and modules).

8504.40.95: Static converters / Inverters (PCS).

A fully integrated, containerized BESS might be classified under a single code or have its components declared separately depending on the import country’s regulations.

Operational Insight: The High Cost of Misclassification “A common pitfall is incorrect HTS classification. On a past project, an imported BESS was initially declared under a general ‘power supply unit’ code. A customs audit reclassified it as ‘lithium-ion batteries,’ triggering a higher tariff rate under Section 301 of the U.S. Trade Act of 1974. This not only resulted in a significant back-payment but also caused a six-week customs hold, leading to project delay penalties. Our standing recommendation is to secure a binding tariff ruling from a licensed customs broker before the first shipment.“

Tariff Calculation Formula:

The formula for the total import cost is methodical:

Customs Value: Typically the CIF Value (Cost of Goods + Insurance + Freight).

Import Duty: Customs Value × Duty Rate (determined by HTS code).

VAT/GST (if applicable): (Customs Value + Import Duty) × VAT/GST Rate.

Comprehensive Impact: A Multi-Scenario Landed Cost Analysis

To truly grasp the impact, we must move beyond a single example and conduct a sensitivity analysis. Let’s analyze a 1MWh containerized BESS shipped from China to Texas, USA.

Note: All figures are illustrative, based on market conditions in Q3 2025. Freight and tariff rates are subject to change.

| Cost Component | Base Case Scenario | Scenario A: Freight Spike (+50%) | Scenario B: FTA Sourcing (0% Tariff) |

|---|---|---|---|

| Ex-Works (EXW) Price | $250,000 | $250,000 | $250,000 |

| --- | --- | --- | --- |

| Logistics Costs | |||

| Inland & Port Fees | $1,550 | $1,550 | $1,550 |

| Ocean Freight | $9,000 | $13,500 | $9,000 |

| Insurance (0.3% of EXW) | $750 | $750 | $750 |

| Total Logistics Costs | $11,300 | $15,800 | $11,300 |

| --- | --- | --- | --- |

| CIF Value (Customs Base) | $261,300 | $265,800 | $261,300 |

| --- | --- | --- | --- |

| Tariffs & Duties | |||

| US Tariff (25% of CIF) | $65,325 | $66,450 | $0 |

| Total Tariffs | $65,325 | $66,450 | $0 |

| --- | --- | --- | --- |

| Local Handling & Fees | |||

| Port/Broker/Inland US | $4,200 | $4,200 | $4,200 |

| --- | --- | --- | --- |

| Final Landed Cost | $328,255 | $336,450 | $266,800 |

| Cost Increase vs. EXW | +$78,255 | +$86,450 | +$16,800 |

| % Increase vs. EXW | ~31.3% | ~34.6% | ~6.7% |

Analysis:

Base Case: The combined logistics costs and tariffs add $76,625 (Logistics $11,300 + Tariff $65,325), representing a 30.65% increase over the factory price. This is a substantial component of the final energy storage system price.

Scenario A (Freight Spike): A 50% spike in ocean freight adds over $8,000 to the final cost, pushing the total increase to nearly 35%. This demonstrates the extreme sensitivity of project budgets to freight market volatility.

Scenario B (FTA Sourcing): By sourcing from a country with a Free Trade Agreement (e.g., Mexico under USMCA), the 25% tariff is eliminated. This single change saves over $65,000 and reduces the cost adder from over 30% to just 6.7%, a game-changing competitive advantage.

Strategic Solutions: Proactive Cost Mitigation

Managing these costs requires a proactive, multi-layered strategy.

Strategic Sourcing & FTA Utilization: As the analysis shows, leveraging Free Trade Agreements is the single most effective method for tariff cost optimization. This requires a deep analysis of rules of origin but yields the highest returns.

Logistics & Contract Management:

Volume Contracting: For consistent shipping volumes, negotiate long-term fixed-rate contracts with freight forwarders to insulate your business from spot market volatility.

Shipment Consolidation: Always prioritize FCL over Less than Container Load (LCL) shipments to minimize the cost per kWh.

Proactive Risk Management:

Bonded Warehousing: For high-volume markets, using a bonded warehouse solution allows you to defer tariff payment until the product is sold domestically. This improves cash flow and provides inventory flexibility.

Contingency Planning: As our experience shows, building time and cost buffers into your project plan is not conservative—it’s essential realism.