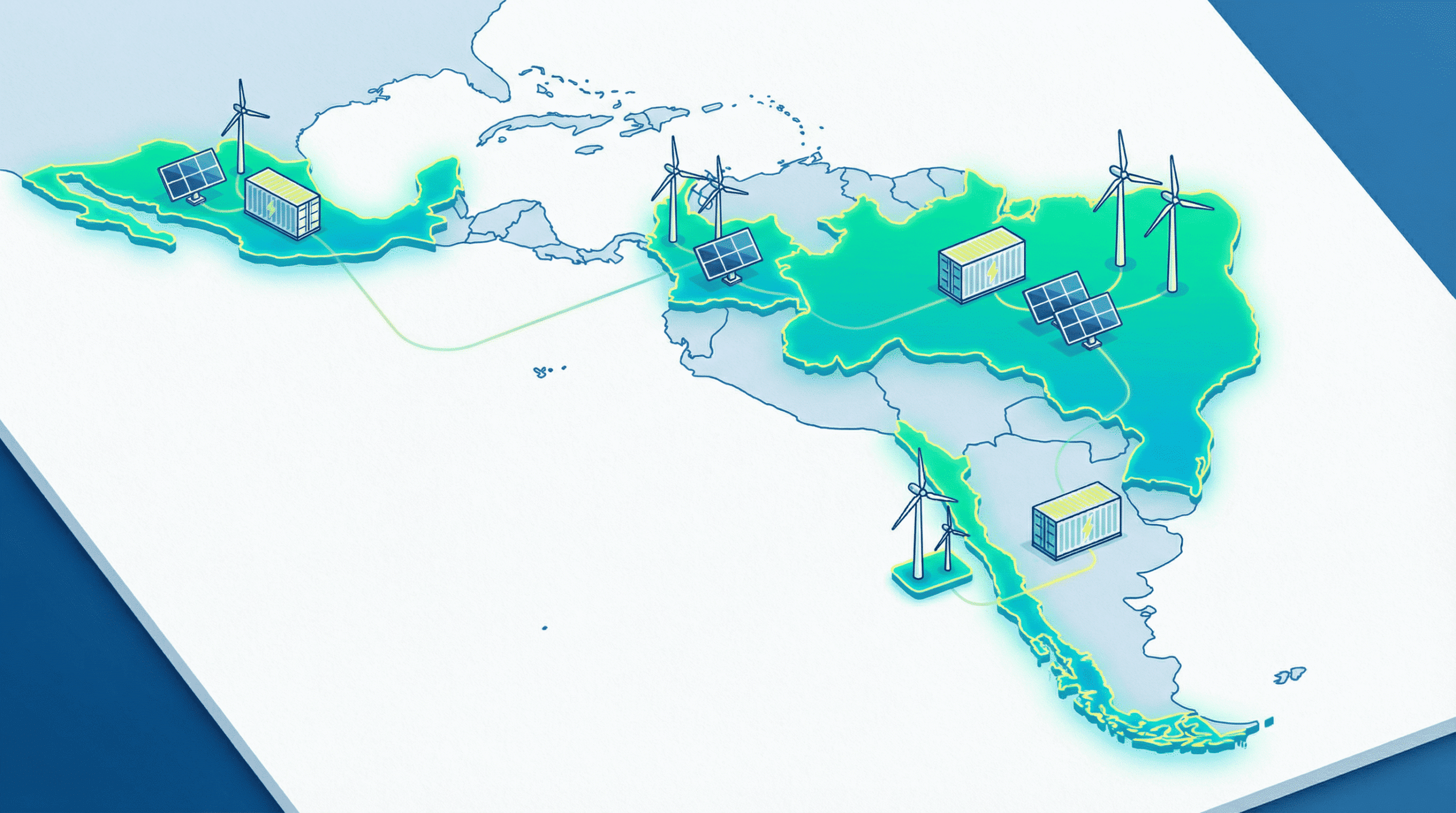

Battery storage OEM Latin America strategies are now central to the success of large‑scale energy storage projects. As Latin American countries rapidly scale solar and wind, utility‑scale battery energy storage systems (BESS) are becoming critical grid assets—not just pilot projects. The International Energy Agency (IEA) notes that Latin America has some of the fastest‑growing renewable markets in the world, while the International Renewable Energy Agency (IRENA) highlights the rising role of storage in integrating variable renewables.

In this environment, choosing the right battery storage OEM Latin America partner and implementing robust operation and maintenance (O&M) practices are decisive for:

- Safety and regulatory compliance

- Long‑term asset reliability and availability

- Battery lifetime and lifecycle cost

- Bankability and investor confidence

Studies by the World Bank and the U.S. National Renewable Energy Laboratory (NREL) consistently show that storage project performance and economics are highly sensitive to O&M strategies. From Xiensolar’s point of view as a system integrator and OEM‑level solution provider, best‑practice O&M must be designed in from day one, tailored to Latin American conditions, and supported by strong local service capabilities.

1. Latin American Context: Why OEM and O&M Must Be Integrated

1.1 Market and regulatory diversity

Latin America is a mosaic of power systems and regulatory frameworks. The IEA’s Latin America analysis and World Bank energy sector diagnostics underline significant differences between countries such as Brazil, Chile, Mexico, Colombia and others in terms of:

- Market design (capacity markets, ancillary service markets, energy‑only structures)

- Grid codes and interconnection requirements

- Environmental and safety regulations affecting energy storage

For a battery storage OEM Latin America project, this means:

- System design and O&M must reflect local grid code requirements for voltage control, frequency response and fault‑ride‑through (often referencing IEEE standards).

- Performance guarantees and O&M contracts must align with specific market products (e.g., frequency regulation, capacity, energy shifting).

- Safety and permitting requirements can differ markedly between jurisdictions, influencing enclosure types, fire protection and access control.

OEMs that can integrate these constraints into equipment design and O&M plans from the outset provide substantial risk reduction for developers and IPPs.

1.2 Climate and environment: harsh but high‑potential

Latin America combines world‑class solar and wind resources with challenging environmental conditions. The Intergovernmental Panel on Climate Change (IPCC) documents rising temperatures, more intense rainfall events and stronger storms in the region.

For BESS, key environmental challenges are:

- High temperature and irradiance (e.g., Atacama Desert, Northeast Brazil): accelerate lithium‑ion degradation and stress power electronics, in line with degradation models compiled by NREL.

- High humidity and salt mist (Caribbean, coastal Brazil, Central America): cause corrosion of enclosures, busbars and control boards, as seen in field data on PV and storage systems analysed by NREL.

- High altitude (Andes): reduced air density lowers cooling performance of air‑cooled systems, often requiring derating or alternative thermal strategies.

- Flood and landslide risks: intensified by extreme weather, a critical issue in infrastructure resilience assessments from the World Bank.

Only a battery storage OEM Latin America supplier that explicitly designs for these conditions—from enclosure IP ratings to thermal management and coatings—can realistically support long‑term O&M success.

1.3 Grid conditions and access

Many prime renewable sites are in remote or weak‑grid regions. The World Bank notes that constrained transmission and poor access roads are common in emerging markets.

This directly affects O&M:

- Weak grids expose PCS and transformers to more frequent voltage and frequency disturbances.

- Long travel times and difficult terrain delay on‑site interventions.

An OEM that combines robust design with remote diagnostics, predictive maintenance and strategically located spares can significantly mitigate these risks.

2. Design for O&M: What a Battery Storage OEM Latin America Provider Should Deliver

Global best practice, as described by NREL and the U.S. Department of Energy, is clear: the most cost‑effective O&M decisions are made at the design stage. For Xiensolar and other serious OEM‑level integrators, “design for O&M” is non‑negotiable.

2.1 Site selection and layout with O&M in mind

Key design choices include:

Location and civil design

- Avoid high‑flood‑risk areas or design adequate elevation and drainage using climate risk tools such as the World Bank Climate Change Knowledge Portal.

- Consider prevailing winds, dust and access for maintenance vehicles in the site layout.

Maintenance access and ergonomics

- Provide safe, clearly marked corridors around containers and equipment.

- Design doors, cable routing and component placement to facilitate inspection and replacement.

These measures reduce service time and safety incidents throughout the asset’s life.

2.2 Modular, redundant architectures

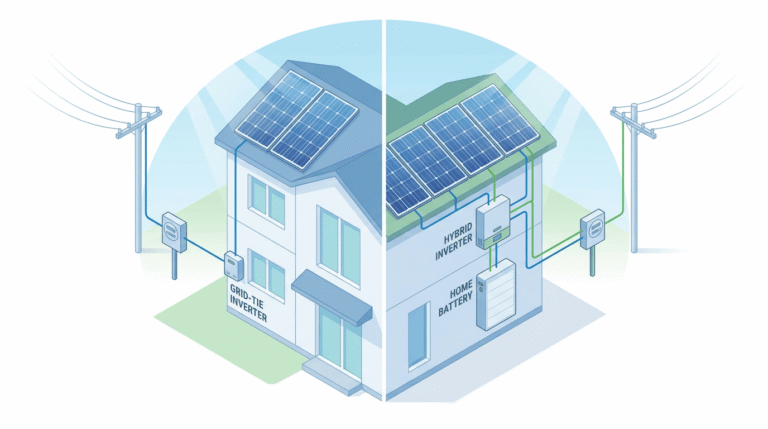

IRENA highlights modular, containerized designs as a best practice for utility‑scale BESS (IRENA storage report). A strong battery storage OEM Latin America partner will:

- Use standardized container or skid modules with repeatable rack and PCS configurations.

- Build redundancy into critical elements such as communication networks, auxiliary DC power and PCS blocks.

Modularity and redundancy enable:

- Faster fault isolation and component replacement

- Continued partial operation during maintenance

- Higher effective availability, supporting contractual guarantees

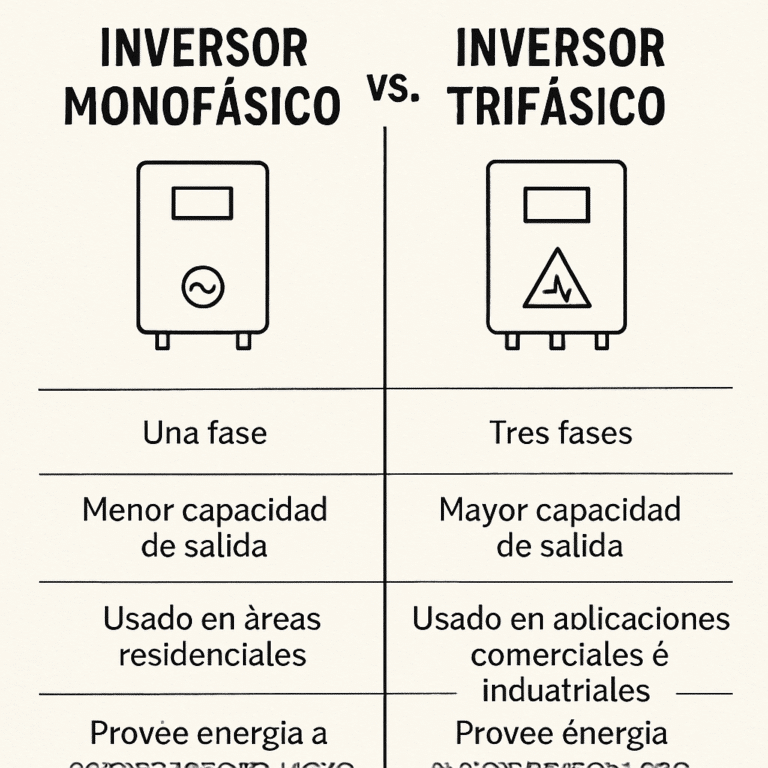

2.3 Technology choices that simplify O&M

Key technology decisions that directly affect O&M include:

Chemistry selection

- Lithium iron phosphate (LFP) is widely considered a safer, thermally stable option for stationary storage, as noted in safety and performance studies referenced by the U.S. Department of Energy and Sandia National Laboratories.

Thermal management system

- Air‑cooled HVAC vs. liquid cooling must be chosen to match local climates. Maintaining narrow temperature bands across cells is crucial to controlling degradation, according to NREL’s aging research.

BMS/EMS and monitoring

- A well‑designed battery management system (BMS) and energy management system (EMS) with granular data, event logging and remote firmware update capability are essential for efficient troubleshooting and optimization.

Standards and certifications

- Compliance with international safety standards such as UL 9540 and test standard UL 9540A—documented by UL—simplifies permitting and insurance in Latin American markets increasingly aligning with global norms.

An OEM that treats O&M as a design criterion rather than an afterthought gives project owners a better starting point for decades of operation.

3. Digital, Data‑Driven O&M for Latin American BESS

3.1 Integrated SCADA–EMS–cloud architecture

Modern BESS operation follows digitalization trends described in the IEA Digitalisation and Energy report. A typical Xiensolar architecture includes:

- SCADA for real‑time equipment monitoring and control at plant and substation level

- EMS for dispatch optimization, constraint management and interaction with market or utility signals

- Cloud analytics for fleet‑wide data storage, trending, reporting and predictive maintenance

This structure enables local autonomy for safety‑critical functions and centralized intelligence for performance optimization.

3.2 Key monitoring metrics and predictive analytics

NREL’s work on PV and storage O&M (NREL O&M report) shows that condition‑based maintenance can significantly reduce lifecycle costs. For BESS in Latin America, important metrics include:

- Battery metrics: cell and module voltages, temperatures, currents, SoC, SOH

- Environmental data: internal and external temperatures, humidity, dust load

- Grid interface metrics: power factor, harmonics and voltage quality, compared with IEEE Std 519 and local grid codes

- Auxiliary systems: HVAC performance, fire detection and suppression system status, DC auxiliary supplies

With sufficient high‑quality data, a battery storage OEM Latin America provider can:

- Deploy anomaly detection algorithms to identify early signs of failure (e.g., temperature hotspots, imbalance growth).

- Build degradation and remaining useful life (RUL) models for batteries, PCS and key auxiliaries, an approach aligned with advanced asset management practices studied by EPRI.

3.3 Cybersecurity as an O&M foundation

Because BESS often connect to utility control centers and cloud systems, cybersecurity must be built into both design and O&M. The NIST Cybersecurity Framework and CISA ICS guidance recommend:

- Network segmentation between operational technology (OT) and corporate IT

- Role‑based access control with multi‑factor authentication

- Secure, logged remote access and regular vulnerability patching

A credible battery storage OEM Latin America partner will integrate these controls into both hardware architecture and O&M procedures.

4. Safety Management and Standards

Safety is non‑negotiable for any large BESS project. International standards and guidelines—such as NFPA 855 for stationary energy storage and UL 9540A for thermal runaway testing—are now de facto reference points for safe design and operation, as described by NFPA and UL.

4.1 Multi‑layer safety by design

Key safety design principles include:

- Use of inherently safer chemistries (e.g., LFP) and conservative cell operating windows

- Proper isolation, fusing and monitoring at string and container level

- Adequate fire detection and suppression tailored to lithium‑ion hazards

- Ventilation and gas management to prevent explosive atmospheres

These measures reflect lessons learned from BESS incidents analysed in the U.S. DOE Energy Storage Safety initiative.

4.2 Operational safety and emergency response

O&M best practices for safety include:

- Continuous monitoring of temperature, smoke and gas sensors, plus insulation resistance where applicable

- Clear alarm hierarchies and automatic safety actions (e.g., safe shutdown, isolation)

- Site‑specific emergency response plans covering fire, abnormal operation and extreme weather, with regular drills involving local fire brigades

Latin American fire authorities are rapidly gaining experience with energy storage, but a battery storage OEM Latin America partner with global incident‑learning and training programs can significantly strengthen site preparedness.

5. Local Service Networks, Spares and Training

5.1 Spares and supply chain planning

The IEA notes that global clean‑energy supply chains, including batteries and power electronics, are concentrated and can face delays. In Latin America, customs and logistics add further complexity.

To mitigate these risks, best practice includes:

- A documented critical spares list: battery modules, BMS boards, PCS control cards, key sensors, HVAC parts and fire system components

- Tiered spares strategy: essential items on‑site, additional inventory in regional warehouses

- Clear contractual responsibility between OEM, EPC and O&M provider for sourcing and stocking spares

5.2 Local talent and partnerships

The clean‑energy workforce gap in emerging markets is highlighted in IRENA’s jobs statistics. For BESS:

- Local technicians and engineers must be trained in high‑voltage safety, battery systems, EMS/SCADA and cybersecurity.

- Structured training and certification, ideally aligned with professional bodies like IEEE, are vital.

- Partnerships with local EPCs and service firms ensure faster response and better cultural alignment.

A strong battery storage OEM Latin America partner will combine global technical standards with local teams and training programs to deliver sustainable, high‑quality O&M.

6. Commercial Models, KPIs and ESG

6.1 O&M contracts and performance guarantees

Drawing from performance‑based infrastructure approaches described in World Bank PPP guidance, BESS O&M contracts should clearly define:

- Technical availability targets and allowed forced outage rates

- Response times for critical alarms and on‑site interventions

- Efficiency and auxiliary consumption metrics

- Safety and training KPIs (e.g., incident rates, completed drills)

These metrics and associated incentives help align owner and OEM/O&M provider objectives over 15–20 years.

6.2 ESG and lifecycle management

Investors increasingly expect robust environmental, social and governance (ESG) performance. The World Bank Environmental and Social Framework and IFC Performance Standards provide references.

For BESS, this implies:

- Responsible management of noise, visual impact and traffic from maintenance activities

- Proper handling and disposal of hazardous materials in line with national laws and principles similar to those outlined by the U.S. EPA

- End‑of‑life planning for batteries, including second‑life applications and recycling, reflecting circular‑economy principles in IRENA’s end‑of‑life studies

A battery storage OEM Latin America provider that integrates ESG and lifecycle thinking into design and O&M gives financiers and regulators greater confidence in long‑term project sustainability.

7. Xiensolar as a Battery Storage OEM Latin America Partner

Xiensolar positions itself as a battery storage OEM Latin America developers and utilities can rely on for integrated design, manufacturing/integration and O&M services. Our approach is built on:

- Design‑for‑O&M: modular, LFP‑based BESS engineered for Latin American climates, grid codes and logistics constraints

- Digital excellence: integrated SCADA/EMS platforms and analytics aligned with methodologies from NREL and Sandia

- Local presence: partnerships with regional EPCs, service providers and training institutions to build strong, multilingual O&M teams

- Lifecycle and ESG mindset: planning for mid‑life augmentation, responsible end‑of‑life management and alignment with international ESG expectations

By combining robust engineering, data‑driven operations, safety leadership and local capacity‑building, Xiensolar helps owners implement true O&M best practices for utility‑scale BESS and turn each project into a safe, reliable and high‑return infrastructure asset.

In summary, working with a capable battery storage OEM Latin America partner—and insisting on rigorous, locally adapted O&M best practices—is one of the most effective ways to ensure that large‑scale BESS projects deliver on their technical, financial and ESG promises across the region’s diverse and demanding environments.