For battery installers, the physical form factor of an energy storage system (ESS) can make or break project timelines, profitability, and safety. As residential and commercial storage markets expand rapidly—documented by agencies such as the International Energy Agency (IEA) and research institutions like the National Renewable Energy Laboratory (NREL)—installers are increasingly choosing between two dominant formats:

- Wall-mounted lithium batteries

- Rack-mounted (or cabinet) lithium batteries

Both rely on similar lithium-ion technologies (often LiFePO₄ for stationary storage), which organizations like the U.S. Department of Energy (DOE) highlight as key to modern energy systems. But for installers, the day-to-day realities of mounting, wiring, servicing, and scaling these systems are very different.

This article compares wall-mounted lithium batteries vs rack batteries specifically from an installer’s perspective—installation time, ergonomics, safety, profitability, and best-fit use cases—so you can standardize smarter and reduce callbacks.

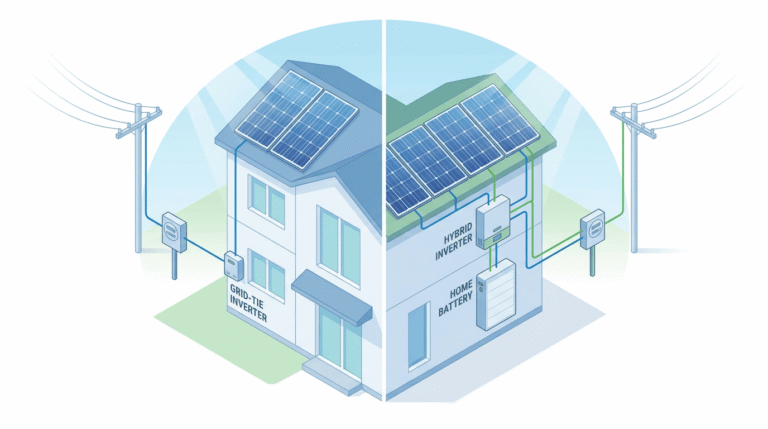

1. Quick Definitions and System Overview

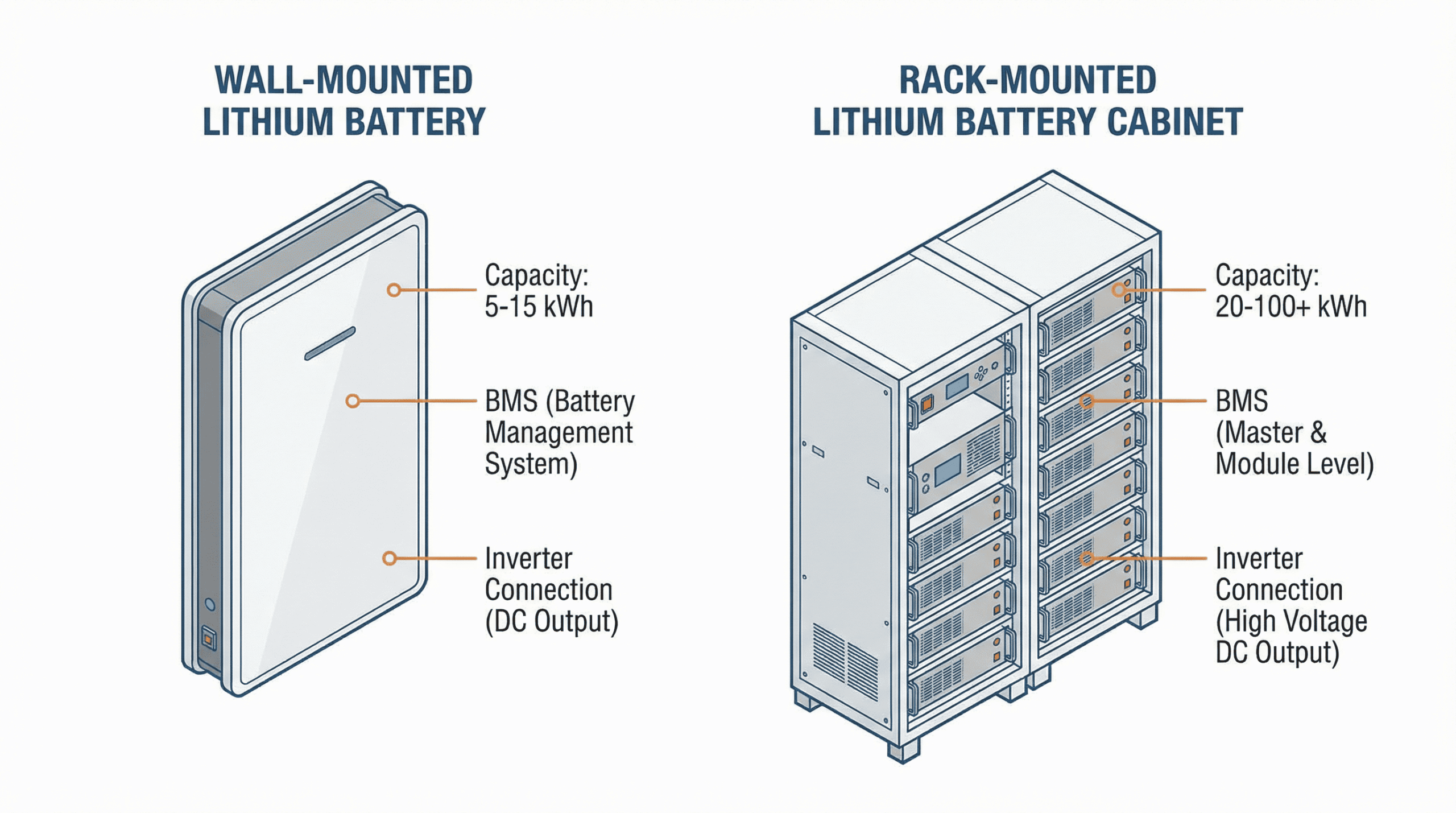

1.1 What Is a Wall-Mounted Lithium Battery?

A wall-mounted lithium battery is typically:

- A single, enclosed unit hung on a wall (garage, utility room, plant room, or exterior wall—where codes allow)

- Often sized for residential or light commercial use (e.g., 5–15 kWh per unit)

- Designed to be visually clean, with most cabling hidden or minimized

- Delivered as an all-in-one or near-all-in-one system (battery modules, BMS, enclosure, disconnects, and in some cases an integrated inverter)

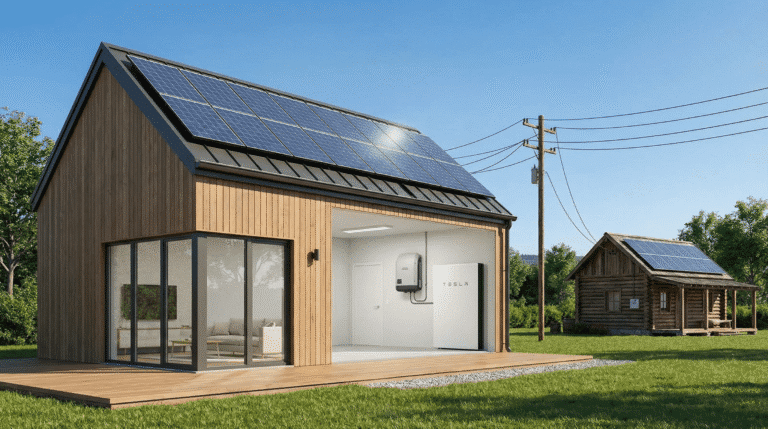

These systems are commonly used in homes with solar PV for backup and self-consumption. Agencies like NREL discuss such applications in their distributed energy resources work, where small-scale storage improves self-consumption and grid resilience.

1.2 What Is a Rack-Mounted Lithium Battery?

A rack-mounted battery system (often in a cabinet) usually consists of:

- One or more standardized battery modules (e.g., 3–5 kWh each)

- A 19″ rack or proprietary cabinet, floor-standing

- Interconnection via DC busbars or cables and external protection devices

Rack systems are common in:

- Commercial and industrial (C&I) sites

- Larger residential or multi-dwelling projects

- Telecom backup and data centers

Their modular nature makes it easy to build from tens to hundreds of kWh in a single cabinet or battery room.

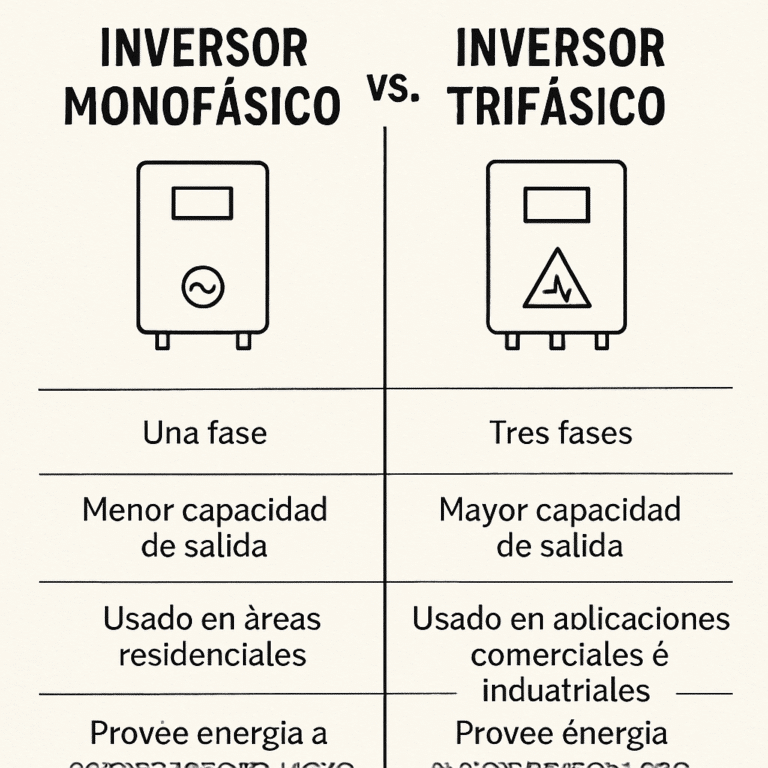

1.3 Shared Core Technologies

Both wall and rack systems typically use:

- Lithium-ion chemistries, especially LiFePO₄ (LFP) for stationary storage, valued for stability and long cycle life, as discussed in DOE and NREL energy storage overviews on energy.gov and nrel.gov.

- An integrated Battery Management System (BMS) that monitors cell voltages, temperature, current, and protects against over/under-voltage and over-current.

- Communication protocols (e.g., CAN, RS485, Modbus) for inverter and EMS integration.

- Compliance with key safety standards such as UL 9540 for energy storage systems—outlined by UL Solutions—and installation requirements driven by codes like NFPA 70 (NEC) and NFPA 855, published by the National Fire Protection Association (NFPA).

The main differences, from an installer’s point of view, come down to how these systems are physically deployed.

2. Key Comparison Factors for Installers

2.1 Installation Time and Complexity

Wall-mounted batteries

- Usually ship as mostly pre-assembled units.

- Steps often include:

- Fixing a mounting bracket

- Hanging the battery

- Running short DC and communication cables to the inverter

- Basic configuration and commissioning

- On straightforward residential jobs with good access, installers can often mount and wire a single wall unit in under half a day, depending on local code requirements.

Rack-mounted batteries

- Require cabinet assembly, module installation, and inter-module wiring.

- More steps:

- Positioning and leveling the rack

- Installing each module in sequence

- Connecting DC busbars or cables, fuses, and disconnects

- Labeling and dressing cables to a professional standard

- For multi-module cabinets, on-site work can easily extend to a full day or more for a small team, particularly when integrating with existing switchgear.

Installer takeaway:

For small systems, wall-mounted batteries usually mean fewer steps and faster deployment, which can significantly reduce labor costs per job.

2.2 Handling, Weight, and Ergonomics

The U.S. Occupational Safety and Health Administration (OSHA) emphasizes safe manual handling to prevent musculoskeletal injuries. This directly affects how installers view wall-mounted vs rack systems.

Wall-mounted units

- Typically heavier per unit (e.g., 50–120 kg / 110–265 lb).

- Often require two-person lifts, and sometimes lifting aids, especially at awkward heights.

- Critical checks:

- Wall strength (masonry vs drywall)

- Fixings and anchors suitable for the load

- Seismic requirements in relevant regions

Rack systems

- Individual modules are usually lighter (e.g., 20–40 kg / 44–88 lb).

- Installers can often move and install these more safely one at a time, reducing strain.

- The cabinet itself is heavy but can be wheeled or levered into place and then secured to the floor/wall.

Installer takeaway:

Wall-mounted batteries concentrate more weight in a single unit, increasing lifting and structural considerations. Rack batteries spread the weight into smaller, more manageable modules, which can be safer and more flexible to handle on-site.

2.3 Space and Site Requirements

Wall-mounted batteries

- Use wall space, freeing up floor space in tight garages or plant rooms.

- Ideal where:

- Floor space is valuable or cluttered

- Customers want a “tidy” wall installation near the inverter

- Limitations:

- Need a strong, structurally sound wall

- May be restricted in some indoor living spaces by codes or fire regulations, which NFPA and local codes address.

Rack batteries

- Occupy floor space but have a compact footprint for larger capacities.

- Work best in:

- Dedicated electrical rooms or basements

- Commercial back rooms or utility spaces

- Can scale vertically within one cabinet, offering high capacity in a small floor footprint.

Installer takeaway:

Small residential sites with tight spaces often favor wall-mounted units; larger electrical rooms and C&I projects usually work better with rack cabinets.

2.4 Scalability and Future Expansion

Organizations like NREL highlight scalability as a core benefit of modern battery systems in their grid storage research. That plays out differently between these two form factors.

Wall-mounted

- Adding capacity generally means adding more wall units, assuming there is physical space and the inverter system supports parallel operation.

- Practical limits:

- Available wall area

- Cable routing complexity

- Aesthetics (multiple boxes on different walls)

Rack

- Designed from the outset for modular expansion:

- Add new modules into spare rack U-space

- Or add another full cabinet alongside the first

- Electrical architecture is usually more straightforward when expanding (common DC bus).

Installer takeaway:

If your typical projects require more than ~15–20 kWh or are likely to expand significantly, rack-based systems usually offer cleaner scalability.

2.5 Safety and Code Compliance

Safety for energy storage systems is governed by evolving standards like NFPA 855 (Standard for the Installation of Stationary Energy Storage Systems) and NFPA 70 (National Electrical Code), overseen by the NFPA. Certification standards such as UL 9540 provide system-level safety guidelines, detailed by UL Solutions.

Key considerations for installers:

Mounting safety

- Wall systems: anchors, pull-out strength, seismic bracing in high-risk regions.

- Racks: floor anchoring, tip resistance, and aisle clearances.

Fire safety and spacing

- Battery location relative to exits, combustible materials, and living spaces.

- Requirements for ventilation, separation distances, and sometimes fire-rated enclosures or rooms.

Electrical safety

- Correct overcurrent protection, disconnecting means, and labeling.

- Coordination with NEC requirements for ESS (e.g., articles that address ESS and battery circuits).

Installer takeaway:

Neither form factor is inherently “safer”—it depends on system design, certification, and proper installation to relevant standards. However, rack systems in a dedicated battery room can sometimes make it easier to meet spacing, separation, and containment requirements on larger projects.

2.6 Aesthetics and Customer Perception

Wall-mounted

- Often designed with a consumer-friendly, “appliance-like” look.

- Visible in garages or utility rooms; many homeowners are proud to show them off alongside solar inverters.

- Can increase customer satisfaction by making the system feel modern and premium.

Rack-mounted

- Look more industrial—metal cabinets, visible louvering, status lights.

- Very acceptable in back rooms, warehouses, data centers, and plant rooms.

- For high-end residential, may need to be placed out of sight to avoid appearing too “industrial.”

Installer takeaway:

For residential work where the system is visible to the homeowner, wall-mounted units generally win on aesthetics.

2.7 Serviceability and Maintenance

Wall-mounted

- Accessed from the front or sides, depending on model.

- If one internal module fails, some products allow in-field module replacement; others may require whole-unit swap, affecting service logistics.

- Firmware updates and diagnostics are typically via front ports or remote connectivity.

Rack-mounted

- Highly serviceable:

- Individual modules can be pulled and replaced without removing the whole stack.

- Clear access to DC busbars, fuses, and breakers at the front of the cabinet.

- Easier to isolate a faulty module, particularly useful where uptime is critical.

Installer takeaway:

For systems where service contracts and uptime matter—C&I, telecom, microgrids—rack systems often provide simpler, safer, and more granular servicing.

2.8 Inventory, Logistics, and Shipping

Wall-mounted

- Larger single units; fewer boxes per project.

- Less SKU complexity for a small residential installer: often one or two battery models and compatible inverters.

- Heavier per box, which could affect shipping and handling.

Rack-mounted

- Multiple modules plus cabinets and accessories.

- More SKUs to manage, but:

- Modules are often universal across multiple project sizes.

- You can standardize on one module model and configure systems from 20 kWh to hundreds of kWh.

Installer takeaway:

High-volume residential installers often prefer the simplicity of wall-mounted SKUs, while commercial-focused companies benefit from the modularity of rack-based inventory.

2.9 Cost Considerations (Installer-Focused)

Direct hardware prices vary widely by manufacturer, but from an installer’s lens, total cost includes:

- Equipment cost (USD/kWh)

- Labor hours for mounting, wiring, and commissioning

- Accessories (racking, mounting rails, conduits, ancillary hardware)

- Travel and time-on-site, including repeat visits

Broad trends:

- Wall-mounted units can carry a slight premium per kWh due to integrated enclosures and consumer design, but they can save labor hours on small installs.

- Rack systems often offer better USD/kWh at higher capacities and, once you exceed a certain kWh threshold, become more cost-efficient overall.

3. Wall-Mounted Lithium Batteries: Pros and Cons for Installers

3.1 Advantages

- Fast deployment for small jobs

- Ideal for <15–20 kWh residential systems.

- Clean, compact visual appearance

- Easy to sell and upsell to homeowners.

- Simplified wiring

- Short DC runs between battery and inverter; fewer field connections.

- Good for standardized, repeatable installs

- Perfect for installers targeting high volume, near-identical residential jobs.

3.2 Disadvantages

- Wall structural requirements

- Extra time for assessment, reinforcement, or alternate mounting solutions.

- Limited scalability

- Multiple wall units can get messy in layout and cable routing.

- Heavier units

- More challenging manual handling; increased injury risk if not managed per OSHA best practices.

- Exposure in tight spaces

- Vulnerable to impact from vehicles or stored items in garages.

4. Rack-Mounted Lithium Batteries: Pros and Cons for Installers

4.1 Advantages

- High scalability and modularity

- A natural choice for tens to hundreds of kWh.

- Easier serviceability

- Swap a single module instead of replacing the whole system.

- Efficient use of floor space

- Tall cabinets with relatively small footprints.

- Professional appearance in plant rooms

- Clean busbars, labeled cabling, and standardized layouts.

4.2 Disadvantages

- Longer on-site assembly time

- Module stacking, wiring, dressing, and testing.

- More components to transport and manage

- Cabinets, modules, and multiple cable sets.

- Less suitable for visible residential spaces

- Often perceived as “industrial hardware” rather than a home appliance.

- Requires dedicated floor space

- Not a good fit for cramped garages or small apartments.

5. Use-Case Scenarios: What Works Best Where?

5.1 Small Residential (Single-Family Homes)

- Typical system: 5–15 kWh, 1–2 days install including PV.

- Constraints: wall space, homeowner aesthetics, budget.

Best fit:

- Wall-mounted lithium battery almost always wins:

- Faster installs

- Cleaner look

- Simple story for the customer (“your battery on the wall”)

Rack systems may make sense in larger homes with a dedicated mechanical room or where future capacity increases are highly likely.

5.2 Large Residential / Luxury Homes

- Higher backup expectations (HVAC, EV charging, pool pumps).

- Total capacity: 20–40+ kWh, sometimes more.

Options:

- Multiple wall-mounted units aligned neatly on a utility wall.

- A compact rack or cabinet system in a plant room.

Trade-offs:

- Multiple wall units can still work, but cable management and wall loading must be carefully designed to meet standards like those promoted by NFPA and UL.

- A rack in a mechanical room offers better scalability and serviceability but must be sold to the homeowner as part of a “professional plant room” solution.

5.3 Small to Medium Commercial Projects

- Examples: small retail, offices, workshops.

- Capacity range: 20–100+ kWh.

Best fit:

- Rack-mounted systems usually dominate:

- Easy to grow from 20 to 80+ kWh in the same cabinet line.

- Better suited to integration with existing switchboards and energy management systems.

Wall-mounted solutions could supplement small commercial sites with constrained plant rooms, but most installers prefer racks for their neat electrical layout and expansion capabilities.

5.4 Industrial and C&I Applications

- High capacity, often hundreds of kWh to multi-MWh.

- Safety, redundancy, and uptime are critical.

Here, standards like NFPA 855 and UL 9540 are core design drivers, as noted by NFPA and UL.

Best fit:

- Rack/cabinet or containerized systems are the default:

- Modular racks in a dedicated battery room.

- Swappable modules and clear segregation for fault management.

Wall-mounted units are rarely used due to practical and regulatory constraints at this scale.

5.5 Off-Grid and Remote Installations

- Challenges: transport, rough roads, limited lifting equipment, harsh environments.

Considerations:

Wall-mounted units:

- Fewer parts to manage but heavier single lifts.

- May be preferable when there is solid wall structure and very limited floor space.

Rack systems:

- Easier to haul individual modules in smaller vehicles.

- Cabinets can be assembled on-site even in containerized microgrids.

Best fit:

Choice depends largely on logistics and on-site infrastructure. Many off-grid professionals favor rack modules in rugged enclosures for flexibility and scalable maintenance.

6. Practical Tips for Installers Choosing Between the Two

6.1 Site Survey Checklist

For wall-mounted batteries:

- Verify wall structure (concrete, brick, stud) and load-bearing capacity.

- Check for code-required clearances from doors, windows, and ignition sources, following local interpretations of NFPA and NEC guidance.

- Plan cable routes that minimize lengths but allow service access.

For rack batteries:

- Confirm floor loading and anchoring options.

- Check ceiling height and clearance for lifting modules into upper rack positions.

- Ensure access pathways for cabinets and future maintenance.

6.2 Match Form Factor to Your Business Model

High-volume residential installers

- Standardize around one or two wall-mounted systems that integrate seamlessly with preferred inverters.

- Develop streamlined workflows, training, and pre-commissioning.

C&I or project-based installers

- Build your portfolio around modular rack systems that cover a wide capacity range.

- Train teams on cabinet wiring, commissioning, and service strategies.

Organizations such as NABCEP offer training and certification programs that help installers demonstrate competence and build trust with clients.

6.3 Reduce Installation Time and Callbacks

- Pre-configure where possible

- Label harnesses, pre-program typical configurations in the warehouse.

- Standardize workmanship

- Use consistent cable routing, labeling, color codes, and documentation.

- Educate customers

- Simple explanations of limitations (e.g., backup loads, depth-of-discharge, noise) reduce misuse and post-install disputes.

7. Cost and Profitability Analysis for Installers

7.1 Comparing Real Installation Costs

When you compare wall-mounted lithium battery vs rack battery, look at:

System X (wall-mounted, 10 kWh residential)

- Slightly higher hardware price per kWh.

- Short install time (e.g., half a day battery work for a two-person crew).

- Minimal accessories beyond standard conduits and breakers.

System Y (rack-based, 20–40 kWh commercial)

- Lower cost per kWh, especially at scale.

- Longer on-site time, but higher contract values.

- Better alignment with multi-year service contracts.

7.2 After-Sales Revenue and Service

- Rack systems lend themselves to ongoing service contracts, including:

- Periodic inspections

- Capacity expansions

- Proactive module replacements

- Wall-mounted systems can still yield service revenue (firmware updates, battery health checks), but replacing or upgrading is often a matter of adding another whole unit rather than a single module.

7.3 Supplier Relationships and Support

Whichever path you choose, prioritize suppliers that:

- Provide clear documentation and training resources, aligned with best practices from bodies like DOE and NREL.

- Offer strong technical support and firmware update paths.

- Have a good track record on warranty handling and spare parts availability.

8. Future Trends in Battery Form Factors

8.1 Hybrid and Modular Designs

Manufacturers are increasingly blurring the lines:

- Stackable wall units that behave like modular racks but still mount on the wall.

- Aesthetic front covers for rack cabinets in residential and light commercial spaces.

This trend reflects broader innovation in energy storage formats documented by agencies such as the IEA and IRENA, highlighted on sites like iea.org.

8.2 Standardization and Interoperability

- Movement toward standard module sizes and open communication protocols.

- More interoperable systems may allow installers to mix manufacturers within standardized racks or frameworks, provided certifications remain intact.

8.3 Implications for Installer Skills

- Installers will need ongoing education to keep up with:

- New code editions (e.g., NFPA 855 revisions).

- Emerging battery chemistries and protection schemes.

- Professional organizations and safety bodies such as NFPA, UL, and OSHA provide resources that can inform training and safe work practices.

9. Decision Framework: Which Is Better for You as an Installer?

Use this quick decision guide when weighing wall mounted lithium battery vs rack battery options.

9.1 Key Questions

Typical project size (kWh)?

- <20 kWh: wall-mounted usually more efficient.

20–30 kWh: rack systems start to shine.

Customer type?

- Homeowners: aesthetics and simplicity → wall-mounted.

- Businesses/industry: scalability and uptime → rack.

Available space?

- Tight garages, small utility rooms → wall.

- Dedicated battery rooms or plant spaces → rack.

Business model?

- High-volume standardized installs → wall.

- Larger, customized projects with service contracts → rack.

9.2 Simple Decision Matrix

Choose Wall-Mounted When:

- You focus on residential solar + storage.

- Typical installs are <15–20 kWh.

- Customer-facing aesthetics matter.

- You want minimal on-site assembly.

Choose Rack-Mounted When:

- You work mainly in C&I or high-end residential with big loads.

- Projects are often >20–30 kWh and may expand.

- Serviceability and long-term maintenance are key revenue streams.

- You have dedicated plant or electrical rooms to work with.

10. Conclusion

From an installer’s perspective, neither form factor is universally “better”. Instead:

Wall-mounted lithium batteries excel in:

- Small to medium residential jobs

- Fast, standardized installations

- Customer-facing spaces where appearance counts

Rack-mounted lithium batteries excel in:

- Larger residential, commercial, and industrial projects

- Scalable, modular architectures

- Environments where serviceability and uptime are critical

By understanding how installation time, ergonomics, safety, scalability, and customer expectations differ between wall-mounted and rack systems, you can align your product portfolio and workflows with your business model—and deliver safer, more profitable, and more reliable energy storage projects.

Always consult current local codes, standards such as those from NFPA and UL, and manufacturer documentation, and work with appropriately trained and certified personnel for ESS installations.