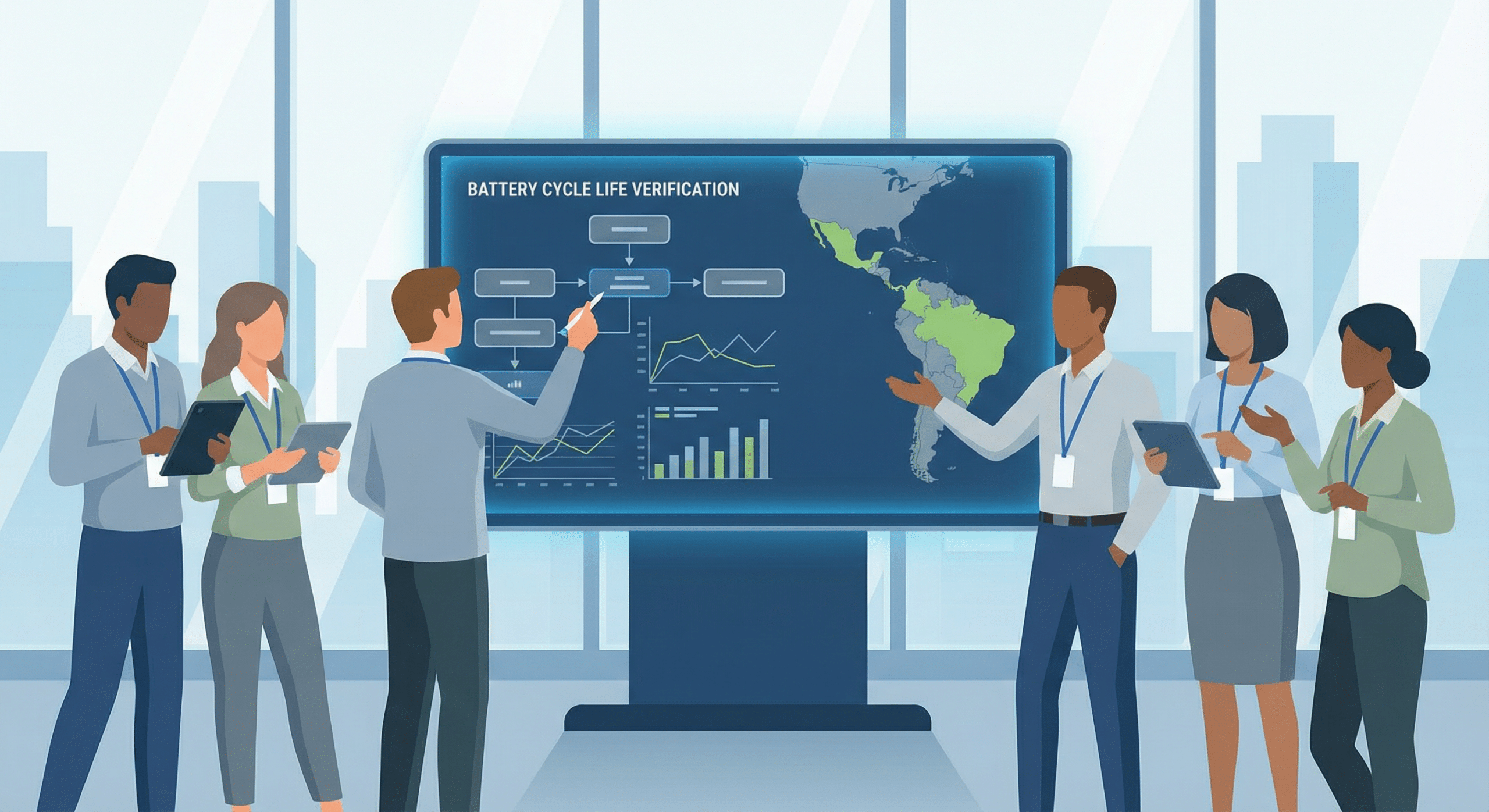

As electrification accelerates across Latin America—from electric motorcycles and delivery trikes to solar‑plus‑storage and commercial microgrids—battery sourcing has become one of the most strategic decisions for wholesalers.

Global EV and battery demand is rising fast, as documented in the IEA’s Global EV Outlook 2024. Much of the hardware installed in Latin America is imported, and many local distributors tell the same story:

“The brochure promises 4,000 cycles and excellent performance, but we have no clear way to check it.”

Without a structured approach to battery cycle life verification and performance validation, wholesalers risk:

- Buying packs that fail years earlier than promised

- Absorbing unexpected warranty and replacement costs

- Damaging their brand and dealer relationships

- Exposing themselves to safety and liability issues

This guide explains how Latin America wholesalers can systematically verify battery cycle life and performance claims, using realistic processes that don’t require a huge in‑house lab. It also shows how a technical partner like Xienauto can help put those processes into practice.

We ground the recommendations in recognized standards and technical sources, including:

- IEC 61960, IEC 62660, IEC 62619

- UN Recommendations on the Transport of Dangerous Goods (UN 38.3)

- Lifetime and degradation research from NREL

- Practical engineering explainers from Battery University

This supports Google’s E‑E‑A‑T (Experience, Expertise, Authoritativeness, Trustworthiness) and gives you references you can reuse in internal SOPs, RFQs and contracts.

1. Get the Fundamentals Right: What Cycle Life and Performance Really Mean

You cannot verify what you don’t define. The first step in battery cycle life verification is understanding how professionals define lifetime and performance.

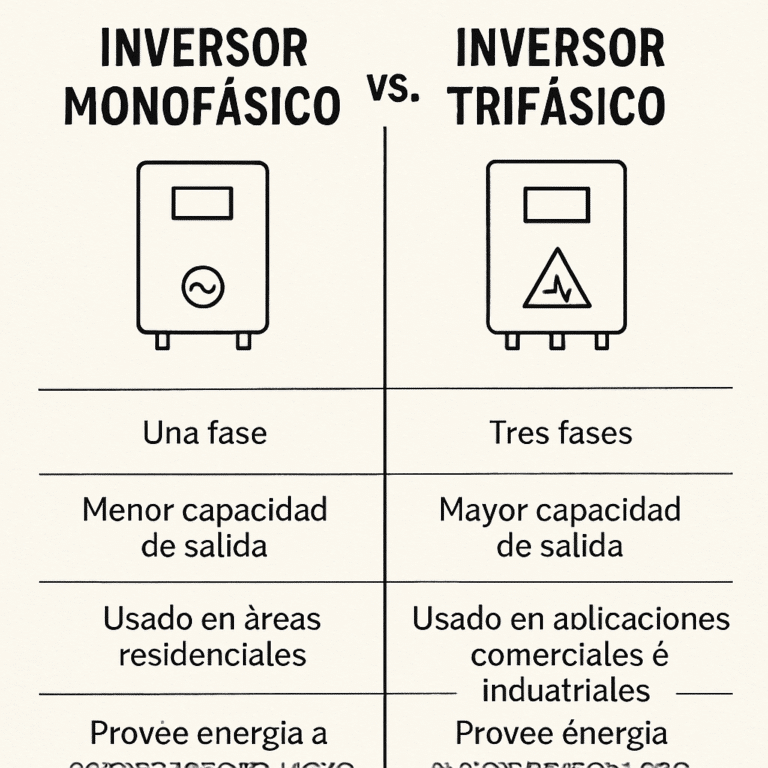

1.1 Cycle life: always ask “Under what conditions?”

In lithium‑ion technology, cycle life is typically defined as:

The number of full charge–discharge cycles until the battery’s usable capacity falls to a specified percentage of its original value (often 80%).

This basic concept is embedded in standards such as IEC 61960 (portable applications) and IEC 62660 (automotive traction cells).

However, the same battery can deliver very different cycle counts depending on:

- Depth of Discharge (DoD)

- 50% DoD (using half the capacity per cycle) can give dramatically more cycles than 80–90% DoD.

- C‑rate (charge/discharge current)

- A 1C discharge drains the battery in 1 hour; 0.5C in 2 hours. High C‑rates increase internal stress and heating.

- Temperature

- High temperatures accelerate side reactions and aging; low temperatures impact plating and performance. Both effects are summarized in the lithium‑ion battery temperature section and practical guides like Battery University BU‑808.

- End‑of‑Life (EOL) criterion

- Many manufacturers quote cycle life until 80% of initial capacity, but some quietly use 70% or lower.

Therefore, a professional cycle life claim should look something like:

“≥3,000 cycles @ 80% DoD, 0.5C charge / 0.5C discharge, 25 ± 2 °C, EOL = 80% of initial capacity.”

If the supplier just says “3,000 cycles” with no conditions, you have no solid basis for evaluation.

1.2 Other performance metrics you should care about

Cycle life is only part of the story. You also need to understand and, where critical, verify:

- Nominal capacity (Ah) and energy (Wh)

- Commonly measured at 0.2C and 25 °C under IEC 61960 conditions.

- Rate capability

- Capacity and voltage behavior at different discharge rates (0.5C, 1C, 2C).

- Essential for e‑motorcycles, delivery trikes and light commercial EVs.

- Internal resistance and power

- Higher resistance means worse voltage sag and more heat under load. Many research efforts, such as those referenced by NREL, track internal resistance growth as a key aging indicator.

- Temperature performance

- Delivered capacity and maximum power at low (0 °C, ‑10 °C) and high (35–45 °C) temperatures.

- Self‑discharge and storage aging

- Capacity loss during months of storage, especially at high state of charge and tropical temperatures.

These metrics together determine if a battery can survive real Latin American duty cycles, not just pass a lab test.

1.3 SOH and EOL: the language of warranties

You will increasingly see:

- SOH (State of Health) – a percentage that reflects how far the battery has aged (often combining capacity and resistance).

- EOL (End of Life) – the SOH below which the battery is no longer considered suitable for its original use (often 70–80%).

Many EV and ESS warranties around the world use EOL thresholds in this range, as visible in manufacturer warranty documents and discussed in energy analyses by the International Energy Agency.

2. Common Ways Cycle Life and Performance Are Misrepresented

Once you understand the definitions, you can start spotting weak or misleading claims.

2.1 Omitting the test conditions

The simplest trick is also the most common:

- “6,000 cycles” with no DoD, C‑rate, temperature or EOL stated.

- “10‑year design life” with no link to any actual cycling protocol or standard.

In practice, a cell might only achieve 6,000 cycles under extremely gentle conditions (e.g. 50% DoD, 0.2C, 25 °C) that are not realistic for daily cycling in Latin American home storage or delivery fleets. Research summarized by Battery University and NREL clearly shows life decreases as DoD, C‑rate and temperature increase.

2.2 Testing “golden samples” only

Another issue is lack of statistical relevance:

- Doing long‑term tests on a handful of hand‑selected cells

- Reporting only “typical” or best‑case data instead of averages and variance

- Providing no information on sample size or distribution

When you receive real production batches, you may see more spread in capacity and higher early failure rates than those optimistic reports suggested.

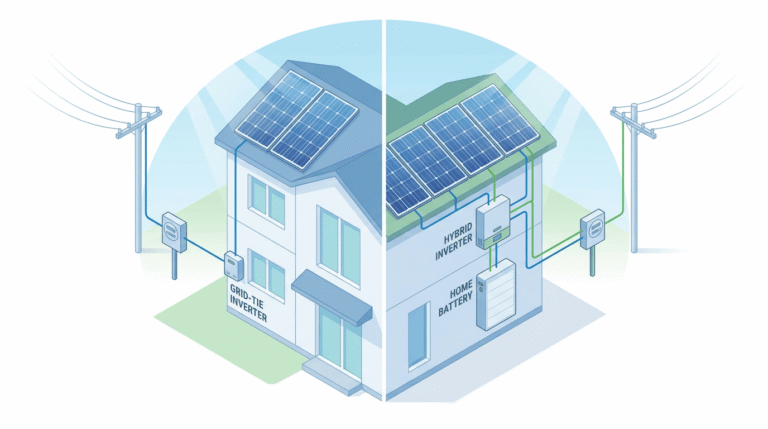

2.3 Confusing safety certificates with performance proof

Wholesalers are often shown:

- UN 38.3 transport reports (part of the UN Recommendations on the Transport of Dangerous Goods)

- Basic safety approvals like IEC 62133

These are important, but they primarily confirm safety and transportability, not long‑term performance or cycle life. They do not validate the specific cycle counts or capacity retention that matter to your customers.

2.4 Using cell‑level data as pack‑level marketing

A further trap is:

- Presenting cell test data (from IEC 61960 or IEC 62660) as if it applies directly to an assembled pack.

Pack reality is affected by:

- BMS settings and algorithms

- Thermal design and cooling/ventilation

- Variability and balancing between cells

Pack‑level lifetime and safety often fall short of idealized cell‑only results, especially in applications without active thermal management—a common situation in Latin America due to cost constraints.

3. A Three‑Level Framework for Verifying Claims

You don’t need a world‑class lab on day one. A structured three‑level battery cycle life verification framework balances cost and risk:

- Level 1 – Desk review of documentation and supplier capability

- Level 2 – Independent sample testing of key products

- Level 3 – Routine incoming inspection for every batch

3.1 Level 1: Desk review and supplier qualification

This is your lowest‑cost filter and should be mandatory for any new supplier.

a) Company and quality background

Request:

- Company registration, factory addresses, annual capacity and main export markets

- Quality certifications like ISO 9001 and, for automotive‑grade plants, IATF 16949

These don’t guarantee performance, but lack of any structured quality system is a serious warning sign.

b) Technical documentation

Ask for complete datasheets covering:

- Electrical characteristics: nominal voltage, capacity, energy, max continuous and peak current

- Environmental limits: operating and storage temperature ranges

- Cycle life claims with full conditions (DoD, C‑rate, temperature, EOL criterion)

- References to relevant standards such as:

c) Safety and transport compliance

For Latin America importers, essential items include:

- Evidence of passing UN 38.3 tests for safe transport

- Safety reports for:

Always check the test house, edition, and test scope to ensure authenticity and relevance.

3.2 Level 2: Independent sample testing

For major product lines, especially those critical to your brand, independent testing is worth the investment.

a) Get neutral samples

Avoid only trusting samples specially prepared for you. Instead:

- Ask the manufacturer to draw samples from standard production lots

- When practical, purchase units from the open market (through retail channels) and test those

- Record serial numbers and batch codes to trace results back to specific shipments

Xienauto frequently helps partners design sampling strategies and coordinate neutral logistics with labs.

b) Design a realistic, cost‑effective test plan

You don’t need to repeat every IEC or UL test; focus on a few high‑value checks:

Initial capacity and efficiency

- Fully charge and discharge several units at 0.2C–0.5C, 25 °C

- Compare measured capacity with rated capacity (as defined in IEC 61960); good manufacturers typically fall within 95–100% on new packs.

Short‑run cycle life test (e.g. 500–1,000 cycles)

- For ESS:

- 80% DoD, 0.5C/0.5C, 25 °C

- For e‑two‑wheelers:

- 80% DoD, 1C discharge, 0.5C charge, 25 °C

- Track capacity periodically and compare decay trends with patterns discussed in NREL’s lithium‑ion lifetime research. Use this as a sanity check against claims of 3,000–6,000 cycles.

- For ESS:

Temperature performance at local extremes

- Repeat capacity tests at:

- 0 °C (or your lowest expected ambient)

- 35–45 °C (common in many Latin American regions)

- Compare results with 25 °C to understand real performance in your climate, reflecting the temperature sensitivity summarized in the lithium‑ion battery article.

- Repeat capacity tests at:

Internal resistance and high‑rate behavior

- Measure internal resistance and voltage drop at 1C–2C discharge; essential for motorcycles and power‑hungry equipment.

c) Where to test

If you don’t have your own lab:

- Partner with local universities, technical institutes or accredited labs that own battery cyclers and environmental chambers.

- For flagship products, consider third‑party labs such as SGS, TÜV, Intertek, etc.

- Work with Xienauto, which can:

- Conduct screening tests in its own facilities, and

- Coordinate formal testing with independent labs when you need neutral reports.

Documented, repeatable test plans—and their results—become powerful tools in negotiations and risk management.

3.3 Level 3: Incoming Quality Control (IQC)

Even if a design is good, production variation can cause batch‑to‑batch issues. Basic IQC on each shipment is critical.

Key elements:

Sampling rules

- Example: inspect 1–3% of packs per shipment or a fixed number per production lot.

Visual and electrical checks

- Look for mechanical damage, swelling, corrosion or label errors.

- Measure open‑circuit voltage (OCV) for each sampled unit and check:

- It is within the manufacturer’s specified storage range.

- There are no significant outliers in the batch.

Spot capacity verification

- For a smaller subset, run 1–2 full cycles at 0.2C–0.5C and compare capacity with:

- Datasheet values

- Previous batch results

- For a smaller subset, run 1–2 full cycles at 0.2C–0.5C and compare capacity with:

Non‑conformance handling

- Define clear thresholds (e.g. average capacity below 95% of rated, excessive spread between units) that trigger escalation.

- Quarantine suspect batches, document findings and start a structured claim process with the supplier.

Xienauto helps partners in Latin America turn these steps into written procedures and provides training so warehouse and QC staff can execute them consistently.

4. Know the Standards: Talking the Same Language as Engineers

Understanding key standards strengthens your position in technical and commercial discussions.

4.1 Performance and industrial standards

Relevant documents include:

- IEC 61960 – Performance, marking and tests for portable secondary lithium cells and batteries.

- IEC 62660 – Performance and reliability tests for lithium‑ion cells used in electric road vehicles.

- IEC 62619 – Safety requirements for secondary lithium cells and batteries for industrial and ESS applications.

These standards describe how to test capacity, cycle life and safety, giving you a shared measurement framework with manufacturers.

4.2 Safety and transport standards

For safety and logistics, look at:

- UN 38.3, part of the UN Recommendations on the Transport of Dangerous Goods – mandatory for air, sea and land transport of lithium batteries.

- IEC 62133 – Safety standard for portable sealed secondary batteries.

- UL 1973 – Safety standard for stationary and motive auxiliary batteries.

- UL 2580 – Safety standard for EV traction batteries.

When suppliers present certificates, always verify:

- The specific standard and edition

- The test house (preferably accredited and recognizable)

- The scope of tests (which items were actually performed)

5. Tailor Verification to Latin America Use Cases

To truly validate performance, tests must reflect how batteries are actually used in Latin America.

5.1 High temperatures and limited cooling

In many Latin American regions:

- Daytime ambient temperatures reach 30–40 °C or higher.

- Batteries are often placed in small, poorly ventilated indoor rooms or street‑level cabinets.

Studies summarized in the lithium‑ion battery article and practical guides like Battery University BU‑808 highlight that high temperatures accelerate aging and can increase safety risk.

For wholesalers, this means:

- Prioritize test data at elevated temperatures (35–45 °C).

- Ensure BMS settings limit charge and discharge in excessive heat.

- Prefer chemistries and designs with proven robustness in hot climates, particularly for ESS and backup systems.

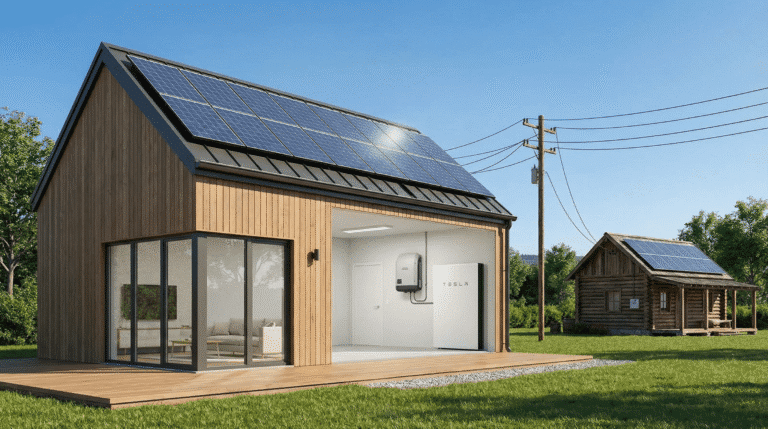

5.2 Deep daily cycling in solar‑plus‑storage

In Latin America, many users:

- Charge from solar during the day and discharge at night, resulting in 1+ full cycle per day.

- Operate at high DoD (70–90%) to maximize return on their investment due to frequent outages or high tariffs.

Therefore:

- Cycle life claims must be evaluated at 80% DoD or higher, not only at 50% DoD.

- To credibly market “10‑year life”, look for 3,000+ cycles at 80% DoD under realistic conditions, aligning with assumptions often used in energy modeling by the IEA and NREL.

5.3 Abuse and high‑power operation in two‑ and three‑wheelers

Electric motorcycles, scooters and trikes in Latin American cities face:

- Frequent full‑throttle accelerations and braking (high C‑rate cycles).

- Poor charging practices (cheap chargers, no active cooling, intermittent power).

- Vibration, dust and mechanical shock on uneven roads.

Verification should therefore:

- Include 1C–2C discharge tests and monitor voltage sag and temperature rise.

- Consider basic vibration and shock tests inspired by traction cell standards such as IEC 62660.

- Validate that the BMS correctly protects against over‑current, over‑temperature, under‑voltage and over‑charge events.

Xienauto works with wholesalers to translate Latin American usage patterns into test profiles and selection criteria that make sense for local fleets and delivery businesses.

6. Put Verified Data into Contracts and Warranties

Battery cycle life verification only protects you if the results are reflected in your contracts and after‑sales policies.

6.1 Make technical specifications legally precise

In purchase agreements, specify:

Cycle life requirement with conditions, for example:

“The battery pack shall provide at least 2,000 full cycles at 80% DoD, 0.5C charge / 0.5C discharge at 25 ± 2 °C, when tested according to IEC 61960 methodology, with remaining capacity ≥80% of rated initial capacity.”

Initial capacity tolerance, e.g.:

“At delivery, measured capacity at 0.2C, 25 °C shall be at least 95% of rated capacity.”

Batch consistency criteria, such as:

- Allowed range of internal resistance across a batch

- Maximum variation in initial capacity between units

These clauses set objective pass/fail criteria for received shipments.

6.2 Align warranty language with measurable triggers

Avoid vague “5‑year warranty” promises. Instead:

- Use time + cycles, e.g. “5 years or 2,000 cycles, whichever occurs first.”

- Define battery failure as:

- Capacity below 70–80% of initial value under defined test conditions

- Abnormal internal resistance growth or repeated critical BMS fault codes

Where BMS logs are available:

- Use recorded cycles, temperatures and faults to differentiate:

- Normal aging within spec

- Abuse or misuse (e.g. chronic over‑temperature, deep over‑discharge)

- Genuine manufacturing or design defects

This approach is consistent with warranty structures used by major EV and ESS manufacturers and aligns with expectations in policy and market analyses by the IEA.

6.3 Xiensolar’s support on contracts and after‑sales

Xienauto helps wholesalers by:

- Providing ready‑to‑adapt technical clauses for specifications and RFQs (English + Spanish/Portuguese).

- Sharing warranty frameworks tuned to different chemistries (LFP vs NMC) and use cases.

- Assisting in technical evaluation of field failures using:

- BMS log interpretation

- Comparison with test data and standards

This helps Latin America wholesalers manage risk while maintaining fair, transparent relationships with both upstream and downstream partners.

7. Digital Traceability: Turning Every Battery into a Data Point

Long‑term quality control requires traceability and data, not just one‑time tests.

7.1 Implement serial number and batch tracking

Each pack (and ideally each module or cell) should have:

- A unique serial number or QR code

- Encoded production information:

- Factory, line and date

- Cell batch codes

At incoming inspection, your team should:

- Scan and store IDs in your inventory or QC system

- Link them to:

- Purchase orders

- IQC results

- Customer or project IDs

This enables you to trace problems back to specific batches and suppliers—standard best practice in quality management across industries.

7.2 Aggregate QC and field data

Even a simple system can provide powerful insights:

- Record IQC results and non‑conformances by batch.

- Register all warranty claims with serial numbers, installation conditions and failure mode.

- Periodically analyze:

- Failure rates by product, supplier, climate region and application

- Dominant root causes (early capacity fade, BMS issues, mechanical damage, installation errors).

These analytics help you:

- Prioritize more reliable products and factories

- Adjust IQC effort by risk level

- Negotiate improvements or compensation with data in hand

7.3 Share data in a continuous improvement loop

Work with suppliers and technical partners based on data, not opinions:

- Provide anonymized or aggregated failure statistics.

- Share representative failed units for joint analysis.

- Agree on corrective and preventive actions (design tweaks, process improvements, new incoming tests).

Xienauto can help wholesalers set up practical data capture tools—from structured spreadsheets to simple system integrations—and define shared formats that make collaboration feasible without complex IT infrastructure.

8. How Xiensolar Helps Latin America Wholesalers Put This into Practice

For many wholesalers, the limiting factor is not intention but technical bandwidth. Xienauto’s role is to act as a battery technology and quality partner, not just a box supplier.

Typical support includes:

Supplier and product pre‑screening

- Evaluating factories for quality management and testing capability

- Reviewing existing IEC/UL/UN papers for each proposed product

Application‑driven selection

- Matching Latin American use cases (climate, duty cycle, grid reliability) to:

- Suitable chemistries (e.g. LFP for ESS, NMC for high‑energy traction where appropriate)

- Appropriate formats and pack designs

- Balancing cycle life, safety and cost to fit each market segment.

- Matching Latin American use cases (climate, duty cycle, grid reliability) to:

Test planning and coordination

- Designing realistic test plans for battery cycle life verification and performance validation.

- Running screening tests in‑house and coordinating third‑party testing when necessary.

- Delivering clear, bilingual reports for internal approvals and downstream marketing.

Process templates and training

- Supplying templates for:

- Supplier qualification checklists

- IQC procedures and test forms

- Failure reporting and analysis workflows

- Training sales, purchasing and technical teams on how to interpret key parameters and flags.

- Supplying templates for:

Continuous optimization based on data

- Updating product recommendations as field data accumulates.

- Helping roll out improved generations of packs as technology and standards evolve.

The end result: Latin America wholesalers can implement robust, practical battery cycle life verification and performance checks without needing to become full‑time battery research labs.

9. Conclusion: Move from Trusting Claims to Owning the Data

As the Latin American market for EVs, two‑wheelers, three‑wheelers and energy storage grows, unverified claims about battery cycle life and performance are becoming a major business risk.

By adopting a structured framework that combines:

- Careful desk review of suppliers and documentation

- Targeted independent testing under realistic local conditions

- Routine incoming QC and digital traceability

…you can transform battery sourcing from a gamble into a controlled, data‑driven process.

With a technical partner like Xienauto, wholesalers don’t have to build all this alone. You gain access to expertise, test planning, documentation templates and analytical support that make professional‑grade verification achievable—at the scale and budget of a regional distributor.

Instead of simply repeating what a foreign datasheet says, you can stand in front of your customers and say:

“These cycle life and performance numbers are not just claims—we’ve verified them under conditions that match how you actually use the batteries.”

That is what real, modern battery cycle life verification looks like in the Latin America wholesale market.

As electric vehicles, electric motorcycles, last‑mile delivery trikes and solar‑plus‑storage systems expand across Latin America, batteries have become one of the most important – and risky – components in the supply chain.

According to the International Energy Agency, global EV and battery demand is growing rapidly, and Latin America is increasingly part of this trend through two‑ and three‑wheelers, light commercial vehicles and distributed energy storage. At the same time, most batteries in the region are imported, often with limited transparency on testing and quality.

For wholesalers, trusting unverified battery cycle life and performance claims can lead to:

- High warranty and replacement costs

- Distributors and end‑users losing trust

- Safety incidents (thermal runaway, fires) that damage your brand and may involve legal liability

This article explains how Latin America wholesalers can verify battery cycle life and performance claims in a structured, affordable way, and how a technical partner like Xienauto can support that process. The approach is based on widely accepted standards and technical resources and is designed to align with Google’s E‑E‑A‑T principles (Experience, Expertise, Authoritativeness, Trustworthiness).

1. Clarify What You’re Verifying: Cycle Life and Performance Basics

Before challenging a manufacturer’s numbers, it’s essential to know what those numbers should actually mean.

1.1 What is battery cycle life?

For lithium‑ion batteries, cycle life is usually defined as the number of full charge–discharge cycles a cell or pack can complete before its usable capacity falls to a stated percentage of its original value (commonly 80%).

This definition is consistent with international standards such as IEC 61960 (for portable lithium‑ion cells and batteries) and IEC 62660 (for automotive traction cells).

Cycle life depends heavily on test conditions, especially:

- Depth of Discharge (DoD) – how much of the total capacity is used in each cycle (e.g. 80% DoD vs 50% DoD). Lower DoD generally extends life.

- Charge/Discharge Rate (C‑rate) – a 1C discharge means full discharge in one hour; 0.5C means two hours, etc. Higher C‑rates stress the battery more.

- Temperature – higher temperature accelerates aging; low temperature can reduce effective capacity and cause lithium plating during charging. This is described in detail in resources such as Battery University.

- End‑of‑life (EOL) criterion – often defined as 80% of initial capacity, but some manufacturers use 70% or other values.

A credible cycle life claim should look like:

“≥3,000 cycles @ 80% DoD, 0.5C charge / 0.5C discharge, 25 ± 2 °C, EOL = 80% of initial capacity.”

If a datasheet only says “5,000+ cycles” without DoD, C‑rate, temperature or EOL, it is technically meaningless.

1.2 Key battery performance metrics

Beyond cycle life, wholesalers in Latin America should understand and, where critical, verify:

- Nominal capacity (Ah) and energy (Wh) – typically measured at 0.2C, 25 °C according to IEC 61960 conditions.

- Rate capability (C‑rate performance) – how much capacity is available at 0.5C, 1C, 2C etc., crucial for e‑motorcycles and three‑wheelers.

- Internal resistance and power – determines voltage drop under load and peak power output.

- Temperature performance – capacity and power at low temperatures (0 °C or lower) and high temperatures (35–45 °C). Technical reviews, such as those summarized in the lithium‑ion battery overview, show strong temperature dependence.

- Self‑discharge and storage aging – how much capacity is lost when a battery is stored at partial or full state‑of‑charge over months.

These metrics together determine whether a battery will actually meet user expectations in demanding Latin American environments, not just pass a lab test.

2. How Cycle Life and Performance Claims Become Misleading

Many wholesalers encounter nice‑looking numbers with little explanation. Recognizing typical “tricks” helps you ask better questions and design the right verification steps.

2.1 Using unrealistically gentle test conditions

Common tactics include:

- Quoting cycle life without specifying DoD, C‑rate or temperature

- Testing at very gentle conditions (e.g. 0.2C, 25 °C, 50% DoD) but marketing the result as if it applied to deep cycling at higher currents

- Presenting internal “R&D test data” as if it were realistic field life

Research compiled by organizations such as the U.S. Department of Energy and NREL shows that higher DoD, higher C‑rates and higher temperatures all significantly shorten lithium‑ion battery life. Without knowing these conditions, the cycle count is impossible to interpret.

2.2 Cherry‑picking test samples

Another frequent issue:

- Testing only a handful of “golden” pre‑production cells

- Reporting the best result, not the average across many cells

- Failing to disclose sample size or statistical spread

When you start receiving regular production batches, capacity spread and early failures may be worse than the few samples used for marketing tests.

2.3 Partial, outdated or irrelevant reports

Manufacturers sometimes provide:

- A single‑page certificate with no curves, conditions or raw data

- Reports that are several years old and refer to earlier versions of the cell

- Reports for safety only (e.g. UN 38.3 transport tests) with no cycle life data

For example, UN 38.3 covers shock, vibration, altitude, short‑circuit and other transport safety tests; it says nothing about long‑term capacity fade or cycle life.

2.4 Marketing language instead of technical definitions

Typical examples:

- “Design lifetime 10 years” or “theoretical 6,000 cycles” without any test reference

- Presenting cell‑level performance as if it applied to a full battery pack, ignoring the influence of BMS, thermal design and pack assembly

Your goal as a wholesaler is to push the conversation from marketing phrases to testable engineering statements.

3. A Three‑Level Verification Framework for Latin America Wholesalers

The good news: you don’t need to build a million‑dollar lab to protect yourself. A three‑level verification framework lets you balance cost and risk:

- Level 1 – Desk review of documents and certifications

- Level 2 – Independent sample testing

- Level 3 – Routine incoming‑goods inspection

3.1 Level 1: Document and qualification review

This first level is low‑cost but filters out many high‑risk suppliers.

a) Company and factory background

Request:

- Business registration, factory locations and annual production capacity

- Main export markets and reference customers (where available)

- Quality management certifications such as ISO 9001 and, for automotive‑grade production, IATF 16949

These standards do not guarantee good batteries, but the absence of any structured quality system is a warning sign.

b) Technical datasheets and definitions

Insist on complete datasheets that include:

- Electrical characteristics: nominal voltage, capacity, energy, max charge/discharge current

- Environmental conditions: operating temperature range, storage temperature

- Cycle life claim with full conditions (DoD, C‑rate, temperature, EOL capacity criterion)

- Mention of relevant standards such as IEC 61960, IEC 62660 or IEC 62619

Compare terminology and definitions with the relevant pages for these standards, for example:

c) Safety and transport certifications

At a minimum, verify:

- UN 38.3 transport test compliance (part of the UN Recommendations on the Transport of Dangerous Goods)

- For portable batteries: IEC 62133 safety compliance

- For EV and stationary systems: applicable standards such as UL 1973 and UL 2580 when relevant

If a supplier cannot provide proper documentation, it is unlikely they can meet consistent performance claims.

3.2 Level 2: Independent sample testing

The second level is to test real samples from the supplier under conditions relevant to your markets.

a) Get unbiased samples

To avoid “hand‑picked” units:

- Request that samples be taken from normal production batches, not engineering prototypes

- When possible, purchase batteries from the open market (through distributors or retailers) for testing

- Ensure serial numbers and batch codes are recorded so you can relate results to actual shipments

Xienauto can help wholesalers design sampling plans and, if required, arrange neutral logistics and handling.

b) Define a practical test plan

You don’t need to reproduce every IEC/UL test. Focus on a small set of high‑impact tests:

Initial capacity and efficiency

- Fully charge and discharge multiple units at 0.2C–0.5C, 25 °C

- Compare measured capacity to the datasheet; many reputable manufacturers target ≥95–100% of rated capacity at these conditions

Short‑term cycle life verification (e.g. 500–1,000 cycles)

- For residential/commercial storage: 80% DoD, 0.5C charge / 0.5C discharge at 25 °C

- For two‑/three‑wheelers: 80% DoD, 1C discharge / 0.5C charge at 25 °C

- Measure capacity every 100–200 cycles; extrapolate cautiously, referencing aging patterns described in research summaries from organizations like NREL and the U.S. DOE.

Temperature performance spot checks

- Test at least one full cycle at:

- 0 °C (or the minimum ambient temperature expected in your target region)

- 35–45 °C (common in Mexico, Brazil, Peru, northern Chile, etc.)

- Compare delivered capacity and voltage curves to 25 °C results; patterns similar to those documented in articles summarizing lithium‑ion temperature sensitivity (see lithium‑ion battery – Temperature sensitivity).

- Test at least one full cycle at:

Internal resistance and power capability

- Measure DC internal resistance and voltage drop at higher currents (e.g. 1C–2C discharge)

- This is critical for vehicles that need strong acceleration and climbing ability.

c) Where to test if you lack a lab

If you do not own test equipment:

- Partner with local universities, technical institutes or test labs that have battery cyclers

- Use accredited third‑party labs (e.g. SGS, TÜV, Intertek) for formal reports, especially for key product lines

- Work with a partner like Xienauto that can:

- run preliminary screening tests in its own facilities

- coordinate more formal tests with independent labs when neutrality is important

These reports become valuable tools in internal decision‑making, negotiations with suppliers, and communication with your own customers.

3.3 Level 3: Incoming Quality Control (IQC) for Every Batch

Even if the design is verified, batch‑to‑batch variation must be controlled.

Key elements of an IQC process:

Sampling rules

- For example: test 1–3% of packs in each shipment, or a defined number per production batch or container.

Quick checks

- Visual inspection: damage, swelling, incorrect labels, missing markings

- Open‑circuit voltage (OCV): check for outliers or unusually low values

- Consistency: spot‑check voltage across multiple units in the same batch

Basic capacity spot‑checks

- For a subset of units, run 1–2 full cycles at 0.2C–0.5C

- Compare to datasheet and to earlier sample test results

Non‑conformance handling

- Define thresholds (e.g. average capacity <95% of label value or too many low‑capacity outliers) for escalation

- Tag, quarantine and document suspect batches; share data with the supplier for resolution

Xienauto can help Latin American wholesalers formalize these steps into a written IQC procedure, complete with simple checklists and training material.

4. Know What Each International Standard Actually Covers

Many marketing brochures list standards to appear credible. Understanding what they mean improves your ability to judge those claims.

4.1 Performance and life standards

Relevant standards include:

- IEC 61960 – for secondary lithium cells and batteries for portable applications; defines performance and test methods for capacity, cycle life and more.

- IEC 62660 – for lithium‑ion cells used in automotive traction batteries.

- IEC 62619 – for industrial applications and energy storage systems (ESS), focusing on safety and performance.

Overviews of these standards are available on references such as IEC 61960, IEC 62660 and IEC 62619.

These standards specify how to measure capacity, life and other metrics, but they do not guarantee a particular level of performance. They provide a common testing language between you and the manufacturer.

4.2 Safety and transport standards

- UN 38.3 (within the UN Recommendations on the Transport of Dangerous Goods) – safety tests required for transporting lithium batteries by air, sea and land.

- IEC 62133 – safety requirements for portable sealed secondary cells and batteries.

- UL 1642, UL 1973, UL 2580 – safety requirements for lithium batteries in various applications (portable, stationary, automotive). Overviews can be found at UL 1973 and UL 2580.

When a supplier references these standards, request:

- The test reports or certificates, including edition and date

- The lab name (preferably accredited)

This helps you separate real compliance from marketing.

5. Tailor Verification to Latin America Use Cases

To align with E‑E‑A‑T principles, technical recommendations must reflect real‑world conditions. Latin America has specific climate and usage patterns that should influence your tests and purchasing criteria.

5.1 High‑temperature climates

Many Latin American markets (parts of Mexico, Brazil, Colombia, Peru, Central America) experience:

- High daytime temperatures (30–40 °C or more)

- Installations in small, poorly ventilated rooms or street‑side enclosures

Scientific and industry literature (summarized, for example, in the lithium‑ion battery article) consistently shows that high temperatures accelerate capacity fade and can increase safety risks.

For wholesalers, this means:

- Request or perform cycle life testing at 35–45 °C, not only 25 °C

- Give preference to chemistries and pack designs that show controlled aging at elevated temperature (e.g. well‑managed LFP cells for ESS)

- Ensure that the BMS includes temperature monitoring and protective limits

5.2 Deep cycling in residential and C&I storage

In many Latin America markets:

- Solar‑plus‑storage systems cycle once or twice per day

- Users often operate at 70–90% DoD to maximize use of stored energy due to grid instability or high tariffs

Best practice (also reflected in guidance from energy storage organizations and technical resources like Battery University) is to:

- Specify and test for 80% DoD or higher in ESS applications

- Target 3,000+ cycles under those conditions if you intend to market “10‑year lifetime” (assuming ~300–365 cycles per year)

Any cycle life claim that only holds at 50% DoD will not reflect these real operating profiles.

5.3 High power and abuse in two‑ and three‑wheelers

Electric motorcycles, scooters and three‑wheelers are booming in Latin America’s dense cities and delivery markets. Their batteries experience:

- Frequent cold‑starts and full‑throttle accelerations (high C‑rate discharge)

- Use of inexpensive chargers and non‑standard charging behavior

- Strong vibration and mechanical shock on rough roads

Verification priorities:

- Test 1C–2C discharge performance, including voltage sag and heat generation

- Check mechanical robustness (basic vibration and shock tests) inspired by automotive standards such as IEC 62660

- Ensure BMS protections (overcurrent, overtemperature, undervoltage) are properly configured and verified

Xienauto can work with wholesalers to design application‑specific test profiles for typical Latin American vehicles and routes, improving the relevance of lab results.

6. Put Verified Parameters into Contracts and Warranty Terms

Technical verification only protects you if the business terms reflect that clarity.

6.1 Specify measurable metrics in purchase agreements

In your contracts with cell or pack suppliers, clearly define:

- Cycle life requirement and test conditions, e.g.:

“≥2,000 cycles @ 80% DoD, 0.5C charge / 0.5C discharge, 25 ± 2 °C, remaining capacity ≥80% of initial (EOL criterion).”

- Minimum initial capacity, e.g. “Measured capacity at 0.2C, 25 °C shall be ≥95% of rated capacity.”

- Consistency limits, such as:

- Maximum allowed spread in capacity and internal resistance across a batch

- Maximum difference in open‑circuit voltage within a shipment

Having these in writing reduces disputes and gives you a clear basis for rejecting non‑conforming shipments.

6.2 Link warranty terms to data and test methods

Instead of open‑ended “5‑year warranty” claims, use:

- Time or cycles, whichever comes first (e.g. 5 years or 2,000 cycles)

- Objective failure definitions, like:

- Capacity <70–80% of initial value when tested at agreed conditions

- Abnormal increase in internal resistance or repeated safety faults

For systems with BMS and data logging, you can:

- Use logs (cycles completed, maximum temperature, fault codes) to distinguish manufacturing defects from misuse or abuse

- Base warranty decisions on data, improving fairness and consistency

This approach is consistent with how many EV and ESS manufacturers manage warranties, as can be seen in publicly available warranty documents and technical notes from industry leaders and energy agencies such as the International Energy Agency.

6.3 How Xiensolar supports contract and warranty design

Xienauto can help Latin America wholesalers by:

- Providing recommended technical specification language in English and Spanish/Portuguese

- Sharing sample warranty structures aligned with realistic performance of different chemistries (LFP vs NMC)

- Helping interpret BMS logs and test results when analyzing field failures or negotiating with upstream suppliers

This reduces internal legal and technical workload while making your policies more robust.

7. Use Digital Traceability to Make Every Battery “Auditable”

Verification is not just a one‑time event; it should be supported by traceability and data throughout the product life.

7.1 Serial numbers, QR codes and batch tracking

Each pack (and ideally each module or cell) should have:

- A unique serial number or QR code

- Encoding of:

- Factory and line

- Production date

- Cell batch codes

At receiving:

- Your team scans and records codes into an inventory/QC system

- You link codes to purchase orders, test results and customers

This is standard best practice in industrial quality management and is consistent with guidance from organizations that focus on battery safety and traceability.

7.2 Centralize QC, test and field data

A simple yet powerful approach:

- Log IQC results for each shipment (capacity tests, visual checks, failures)

- Record warranty claims with serial numbers, installation dates and failure descriptions

- Regularly analyze:

- Failure rate by supplier, cell type, batch or application

- Most frequent failure modes (early capacity fade, BMS faults, mechanical damage, etc.)

This data‑driven approach lets you adjust:

- Which factories you trust the most

- Which product lines are truly suitable for hot climates or deep cycling

- How strict your incoming inspection needs to be for each supplier

7.3 Collaborate on data with suppliers and partners

Share summarized data with your suppliers and technical partners:

- Provide field failure statistics and representative examples

- Request root cause analysis (RCA) for serious incidents

- Align on corrective actions (process improvements, design changes, extra IQC measures)

Xienauto can provide lightweight digital tools (from structured spreadsheets to simple interfaces or API recommendations) that help Latin American wholesalers start with basic traceability and scale up over time.

8. How Xienauto Helps Latin America Wholesalers De‑Risk Battery Sourcing

For many wholesalers, the barrier is not willingness but limited internal engineering resources. A partner like Xienauto can help close that gap:

Pre‑qualification of manufacturers

- Screening factories for quality systems, test capability and standard compliance

- Consolidating documents (IEC/UL/UN test reports, ISO/IATF certificates) in a transparent package

Application‑driven selection

- Matching Latin American use cases (climate, grid stability, vehicle types) with:

- appropriate chemistries (e.g. LFP vs NMC)

- suitable cycle life vs. cost trade‑offs

- Providing comparative data so wholesalers can choose the best fit for their markets

- Matching Latin American use cases (climate, grid stability, vehicle types) with:

Test planning and coordination

- Defining pragmatic test plans (500–1,000 cycles, temperature points, C‑rates) that reflect field usage

- Running preliminary tests in‑house or coordinating with accredited labs

- Delivering bilingual reports (EN + ES/PT) suitable for internal decision‑making and downstream customer communication

Process templates and training

- Helping wholesalers build:

- Supplier technical evaluation checklists

- Incoming QC procedures

- Failure analysis and escalation workflows

- Providing simple training decks for sales and technical staff

- Helping wholesalers build:

Continuous improvement and new product introduction

- Adjusting recommendations based on real failure data and new use cases

- Assisting with migration to improved chemistries or updated pack designs as standards and market expectations evolve

By combining technical depth with practical tools, Xienauto’s role goes beyond product supply to become a long‑term quality and performance partner for Latin America wholesalers.

9. From Trusting Claims to Trusting Data

Battery cycle life and performance claims are easy to print on a datasheet and hard to realize in the field – especially under hot climates, deep cycling and challenging charging behavior common in Latin America.

By implementing a structured approach:

- Level 1 – rigorous desk review of documents and standards

- Level 2 – targeted independent testing based on real regional use cases

- Level 3 – ongoing incoming QC with digital traceability

…wholesalers can dramatically reduce the risk of:

- Overpaying for batteries that don’t meet advertised life

- Suffering high warranty and replacement costs

- Facing reputational and safety issues that threaten long‑term business

Working with a technical partner like Xiensolar allows Latin America wholesalers to put this framework into practice without needing a large internal engineering team. The result is simple but powerful: you stop buying marketing promises and start buying measured, verified performance.