As the world pivots towards renewable energy sources like solar and wind, the need for effective energy storage battery solutions has become paramount. These batteries are the linchpin of a stable, modern grid, ensuring power is available even when the sun isn’t shining or the wind isn’t blowing. However, the market is flooded with competing technologies, making the battery selection process a complex challenge for businesses, homeowners, and even EV manufacturers. Choosing the wrong type can lead to poor performance, excessive costs, and safety risks.

This guide provides an expert-level comparison of the three leading contenders in the energy storage space: the established lithium battery, the emerging sodium battery, and the futuristic solid-state battery. By understanding their core principles, advantages, and limitations, you can make an informed decision tailored to your specific needs.

The Main Types of Energy Storage Batteries

To make the right battery selection, we must first understand the fundamental characteristics of each technology. The choice of energy storage battery will profoundly impact the efficiency, cost, and safety of your system.

Lithium-ion Battery: The Incumbent Champion

A lithium battery, specifically the lithium-ion type, is an electrochemical cell where lithium ions move from the negative electrode (anode) through an electrolyte to the positive electrode (cathode) during discharge, and back when charging. This technology has dominated the market for decades due to its impressive performance metrics.

How it Works: The most common chemistries are Lithium Iron Phosphate (LFP) and Lithium Nickel Manganese Cobalt Oxide (NMC). In both, lithium ions are “intercalated” or held within the crystal structure of the anode (typically graphite) and cathode materials. The liquid electrolyte facilitates this ion transfer.

Applications and Pros & Cons:

Advantages:

High Energy Density: Lithium-ion batteries pack a lot of power into a small, light package. NMC batteries can achieve energy densities of 200-270 Wh/kg, making them ideal for electric vehicles (EVs) where weight and space are critical. (Source: U.S. Department of Energy)

Mature Manufacturing: A well-established global supply chain has driven down costs significantly over the past decade. The average price of a lithium-ion battery pack fell to $139/kWh in 2023. (Source: BloombergNEF)

High Efficiency: They boast excellent round-trip efficiency, often exceeding 90%, meaning very little energy is lost during charge and discharge cycles.

Disadvantages:

Cost & Material Scarcity: Key materials like lithium, cobalt, and nickel are geographically concentrated and subject to price volatility. Cobalt, in particular, has been linked to unethical mining practices.

Safety Concerns: The use of flammable liquid electrolytes creates a risk of thermal runaway—a dangerous chain reaction that can lead to fires—if the battery is damaged or managed improperly.

Limited Operating Temperature: Performance degrades significantly in extreme cold or heat, often requiring complex and costly thermal management systems.

The lithium battery remains the go-to choice for many applications, but these disadvantages have paved the way for new challengers.

Sodium-ion Battery: The Cost-Effective Challenger

A sodium battery, or sodium-ion battery, functions almost identically to its lithium-ion counterpart. The key difference is that it uses sodium ions as the charge carrier instead of lithium ions. This seemingly small change has massive implications for cost and scalability.

How it Works: Like lithium-ion, a sodium battery relies on the intercalation of ions into anode and cathode materials. As sodium is a larger ion than lithium, the host materials must have a more open structure to accommodate it, which presents unique material science challenges.

Advantages and Limitations:

Advantages:

Abundant & Cheap Materials: Sodium is one of the most abundant elements on Earth, found globally in rock salt and seawater. This eliminates the geopolitical and scarcity issues associated with lithium. Raw material costs for sodium-ion cells are estimated to be 20-40% lower than for LFP cells. (Source: International Energy Agency – IEA)

Enhanced Safety: Sodium-ion chemistries are generally more stable and less prone to thermal runaway. They can also be safely discharged to zero volts, making transportation and storage significantly safer and cheaper.

Wide Operating Temperature: They exhibit excellent performance in cold weather, retaining over 85% of their capacity at -20°C (-4°F), a major advantage over most lithium-ion types.

Limitations:

Lower Energy Density: Currently, commercial sodium-ion batteries offer a lower energy density (around 140-160 Wh/kg) than mainstream lithium-ion batteries. This makes them less suitable for applications where weight and space are primary constraints, like long-range EVs.

Less Mature Supply Chain: The manufacturing ecosystem for the sodium battery is still in its infancy. While it can leverage much of the existing lithium-ion production infrastructure, scaling up will take time.

Lower Cycle Life (Historically): Early sodium-ion prototypes had a shorter cycle life, though recent advancements have pushed commercial cells to over 3,000 cycles, comparable to some LFP batteries. (Source: CATL Press Release)

The sodium battery is poised to become a dominant energy storage battery for stationary applications where low cost and safety are more important than energy density.

Solid-State Battery: The Technology of the Future

A solid-state battery represents a paradigm shift in battery design. It replaces the flammable liquid electrolyte used in conventional lithium-ion and sodium-ion batteries with a solid, non-flammable material, such as a ceramic, polymer, or glass.

How it Works: The solid electrolyte acts as both the medium for ion transport and the physical separator between the anode and cathode. This design opens the door to using advanced, high-energy electrode materials, most notably a pure lithium metal anode.

Future Prospects and Technical Challenges:

Advantages (Projected):

Unmatched Safety: Eliminating the liquid electrolyte virtually removes the risk of fires, making this energy storage battery technology inherently safer.

Massive Energy Density: By enabling a lithium metal anode, solid-state battery technology could theoretically double the energy density of today’s best lithium-ion batteries, potentially reaching 400-500 Wh/kg. This would be a game-changer for EVs, enabling 1,000-kilometer ranges. (Source: QuantumScape Data)

Longer Lifespan & Faster Charging: Solid electrolytes are less prone to the degradation reactions that limit the life of liquid-based cells. Their stability could also allow for ultra-fast charging, potentially 10-80% in under 15 minutes.

Technical Challenges:

Manufacturing at Scale: Producing large, defect-free layers of solid electrolyte is extremely difficult and expensive. The current manufacturing processes are far from being commercially viable.

Interface Stability: Maintaining a stable, low-resistance connection between the solid electrolyte and the solid electrodes over thousands of cycles is a major engineering hurdle.

High Cost: The materials and complex manufacturing processes make the solid-state battery prohibitively expensive for most applications at present.

The solid-state battery holds incredible promise, but it is likely still 5-10 years away from widespread commercial availability. It remains a key focus for R&D in the energy storage battery sector.

Key Factors for Your Battery Selection

An effective battery selection process goes beyond the basic chemistry. As a procurement expert, I evaluate potential solutions based on four critical pillars: performance, longevity, safety, and cost.

Energy Density and Capacity Needs

Energy density (measured in Wh/kg or Wh/L) dictates how much energy a battery can store for its weight or volume. Capacity (measured in kWh or MWh) is the total amount of energy the system can store.

How to Choose:

High-Density Applications (EVs, Consumer Electronics): For these, space and weight are critical. The goal is to maximize range or runtime. NMC lithium battery technology is the current leader here, with the solid-state battery being the ultimate goal.

Low-Density Applications (Grid/Stationary Storage): For large-scale projects like utility grids or commercial buildings, the physical footprint is less important than the total cost per kWh. Here, the lower energy density of an LFP lithium battery or a sodium battery is perfectly acceptable, as their lower cost and longer lifespan are more valuable. A key metric is the energy storage battery energy density, but its importance is application-dependent.

Cycle Life and Maintenance Costs

Cycle life is the number of charge-discharge cycles a battery can endure before its capacity degrades to a certain point (typically 80% of its original capacity).

Battery Life Comparison:

NMC Lithium Battery: 1,000 – 2,500 cycles.

LFP Lithium Battery: 3,000 – 6,000+ cycles.

Sodium Battery: 3,000 – 5,000+ cycles and improving.

Solid-State Battery (Projected): Potentially 10,000+ cycles, though not yet commercially proven.

Reducing Maintenance Costs: A longer cycle life directly translates to a lower Levelized Cost of Storage (LCOS), a critical metric for any energy storage battery project. Choosing a battery with a higher cycle life, like LFP or sodium battery, for a daily-cycling application means the system will last longer before needing a costly replacement. This is a crucial consideration when evaluating the total cost of ownership, not just the upfront price. The energy storage battery life is a primary driver of long-term value.

Safety and Stability

Energy storage battery safety is non-negotiable. The consequences of a battery fire can be catastrophic, making this a top consideration in any battery selection process.

Safety Comparison:

Lithium Battery: LFP chemistry is significantly safer and more thermally stable than NMC. However, both use flammable liquid electrolytes, so a robust Battery Management System (BMS) and thermal management are essential to prevent thermal runaway.

Sodium Battery: Generally considered safer than lithium-ion due to its more stable chemistry and ability to be fully discharged for transport.

Solid-State Battery: The safest of all. By eliminating the flammable liquid, it fundamentally designs out the primary fire risk.

How to Evaluate Stability: When procuring an energy storage battery system, demand to see certifications (e.g., UL 9540A) that test for thermal runaway propagation. A good system will not only have a safe cell chemistry but also multiple layers of protection, including an advanced BMS, integrated cooling/heating, and fire suppression systems.

Market Trends and Technological Development

The energy storage battery market is one of the most dynamic sectors in the world. Understanding current trends is key to making a future-proof battery selection.

Lithium Battery: Market Position and Future

The lithium battery market is mature but still evolving. It remains the dominant technology, but the focus is shifting.

Market Trends: LFP is rapidly gaining market share from NMC, especially in stationary storage and standard-range EVs, due to its lower cost and higher safety. It’s projected to become the leading chemistry globally. (Source: Wood Mackenzie)

Technological Innovation: Research continues on silicon anodes to boost energy density and on recycling processes to create a circular economy and mitigate material supply risks. This ongoing battery technology innovation ensures the lithium battery will remain competitive.

Sodium Battery: The Rise of a Challenger

The commercialization of the sodium battery is accelerating.

Commercial Progress: Major manufacturers like China’s CATL and HiNa Battery have begun mass production. We are seeing the first EVs powered by sodium-ion batteries and the deployment of the first grid-scale energy storage battery systems using this technology.

Technical Hurdles: The primary challenge is improving energy density to make it more competitive in mobile applications. Further scaling of the supply chain is also needed to realize its full cost-reduction potential. The sodium-ion battery is a technology to watch closely.

Solid-State Battery: The Future Outlook

The solid-state battery is the long-term bet for the industry.

Breakthroughs and Challenges: Companies like QuantumScape, Solid Power, and Toyota have demonstrated promising results with prototype cells, but the challenge of affordable, high-volume manufacturing remains. The transition from lab to factory floor is the final, most difficult step.

Application Prospects: EVs are the primary target market due to the massive impact a breakthrough would have on range and safety. Once costs come down, this future battery technology could also penetrate premium stationary storage and aerospace applications.

Choosing the Right Energy Storage Battery by Application

The optimal battery selection is always a function of the use case.

Commercial and Industrial (C&I) Applications

Needs: High power for peak shaving, long duration for demand charge management, and high cycle life for daily use.

Recommendation: The LFP lithium battery is currently the best choice due to its excellent cycle life, safety, and proven reliability. As costs decrease and the supply chain matures, the sodium battery will become an extremely compelling alternative for commercial energy storage battery systems, especially in colder climates.

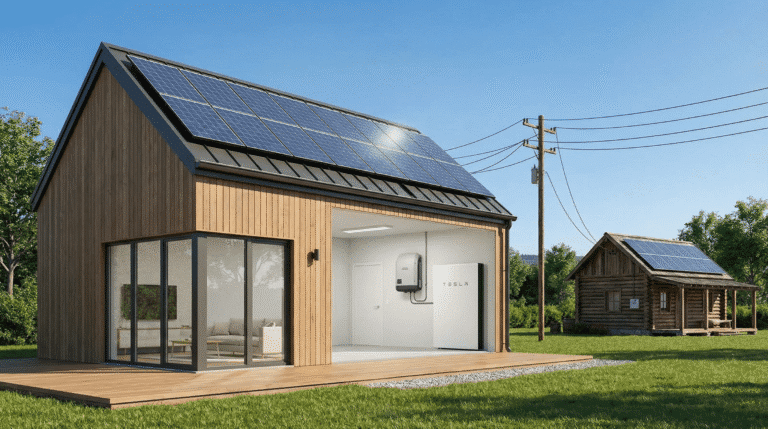

Residential Energy Storage

Needs: High safety, compact size, sufficient capacity for overnight use (e.g., 10-20 kWh), and affordability.

Recommendation: LFP is the clear winner for home energy storage batteries. Its outstanding safety profile provides peace of mind for homeowners. The sodium battery is a strong future contender in this space as well, once residential-sized systems become widely available.

Electric Vehicle (EV) Applications

Needs: The highest possible energy density for maximum range, fast charging capability, and uncompromising safety.

Recommendation: High-nickel NMC and NCA lithium battery chemistries currently dominate the long-range EV market. LFP is the choice for standard-range models. The entire automotive industry is eagerly awaiting the commercialization of the solid-state battery, which promises to solve the core challenges of range anxiety and charging time for electric vehicle batteries.

Evaluating the Cost-Benefit of an Energy Storage Battery

A smart procurement decision hinges on a thorough analysis of the energy storage battery cost benefits.

Initial Investment vs. Return on Investment (ROI)

The upfront cost, or Capital Expenditure (CAPEX), is often measured in dollars per kilowatt-hour ($/kWh).

Cost Comparison:

Lithium Battery (LFP): ~$130-160/kWh at the pack level.

Sodium Battery: Projected to be 20-40% cheaper than LFP once at scale.

Solid-State Battery: Currently thousands of dollars per kWh; not yet commercially priced.

Calculating ROI: The energy storage battery investment return depends on your application. For a business, it’s calculated by comparing the project cost against the savings from reduced electricity bills (peak shaving) or revenue from grid services. A lower initial investment from a sodium battery could significantly shorten the payback period.

Long-Term Operational Costs

Operational Expenditure (OPEX) includes maintenance, efficiency losses, and battery degradation/replacement.

OPEX Comparison: A battery with a longer cycle life (like LFP or sodium battery) will have a lower OPEX because the battery pack (the most expensive component) will not need to be replaced as soon. This is a critical factor in the battery operational cost and overall LCOS. Always factor in the cost of replacement when modeling the finances of a 20-year project.

Conclusion: Making the Right Choice for Your Needs

The energy storage battery landscape is evolving rapidly. The battery selection process requires a careful balancing of performance, lifespan, safety, and cost.

The lithium battery, particularly the LFP chemistry, is the mature, reliable, and often ideal choice today for most stationary storage applications and standard-range EVs.

The sodium battery is the immediate challenger, offering a future of lower costs, greater resource security, and enhanced safety. It is poised to dominate the stationary energy storage battery market and find a niche in cost-focused EVs.

The solid-state battery remains the ultimate goal. It promises to revolutionize the industry, especially for EVs, but is not yet a commercially viable option.

The best choice is not about finding the single “best” technology, but about identifying the right tool for the job. By carefully analyzing your specific application needs—be it powering a factory, a home, or a car—against the distinct profiles of these three technologies, you can make a strategic investment that delivers value, reliability, and safety for years to come.