Introduction

The proliferation of Battery Energy Storage Systems (BESS) marks a pivotal shift in the energy sector. However, deploying this technology effectively is not a matter of simple procurement; it is a complex engineering challenge. A generic, off-the-shelf BESS is a blunt instrument in a field that demands surgical precision. The difference between a financially successful project and a costly underperformer lies in a rigorous, data-driven customization process. For any serious investor or facility manager, the critical question is not just what system to buy, but how that system is specified, designed, and integrated.

This article provides a transparent, engineering-first overview of our methodology for developing a customized battery energy storage system. We will move beyond marketing claims to detail the systematic processes, industry standards, and financial modeling that form the foundation of a high-performance, safe, and profitable energy storage solution. We will cover our approach to load profile analysis, lifecycle cost calculation (LCOE), advanced safety design compliant with NFPA 855 and UL 9540, and share insights from our field experience.

The Core Methodology of BESS Customization

A successful customized battery energy storage system is born from a multi-stage process where each step is informed by empirical data and proven engineering principles. This is our blueprint.

1.1 Load Profile Analysis: The Cornerstone of Design

Before any hardware is considered, we must build a precise “load portrait” of the client’s facility. This is the non-negotiable first step.

- Data Acquisition: We analyze a minimum of 12 months of 15-minute interval electricity usage data. This high-resolution data is critical to capture the true dynamics of consumption, including instantaneous peaks (kW) and total energy usage (kWh).

- Statistical Modeling: From this data, we model key parameters:

- Peak Demand & Duration: Identifying the magnitude and duration of the highest loads, which informs the system’s required power rating (kW).

- Load Duration Curve: Plotting the amount of time the facility spends at different power levels, which helps optimize the energy capacity (kWh).

- Baseload Analysis: Determining the minimum continuous power draw.

- Variability & Ramping: Analyzing how quickly the load changes, which is critical for applications like frequency regulation or smoothing renewable generation.

This analysis ensures the BESS is sized correctly, preventing the cardinal sins of oversizing (wasted capital) or undersizing (failure to meet objectives).

1.2 Cycle Life, Degradation Modeling, and LCOE Calculation

A battery is a depreciating asset. We model its financial viability using the Levelized Cost of Storage (LCOE), the most accurate metric for comparing different solutions.

- LCOE Formula: The LCOE represents the total cost to store and discharge one megawatt-hour (MWh) of electricity over the system’s lifetime. A simplified representation is:

- Key Inputs for Accurate LCOE:

- Cycle Life vs. Depth of Discharge (DoD): We use manufacturer-provided degradation curves, which show the trade-off between how deeply a battery is discharged and its total expected lifecycle. For example, a Lithium Iron Phosphate (LFP) battery might be rated for 6,000 cycles at 80% DoD but over 10,000 cycles at 60% DoD. Our EMS strategy is designed to optimize this trade-off.

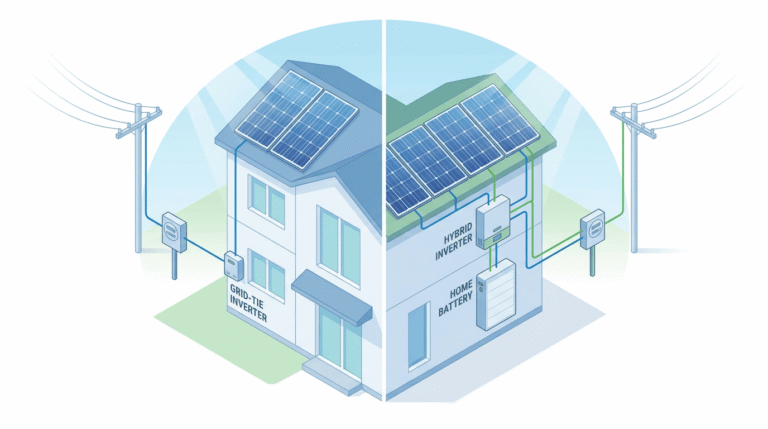

- Round-Trip Efficiency (RTE): We model the RTE not just of the battery but of the entire system, including the Power Conversion System (PCS/inverter) and thermal management parasitics, which typically results in a system RTE of 85-92%.

- Augmentation Strategy: We plan for battery degradation by modeling capacity augmentation—the scheduled addition of new cells during the project’s life to maintain its required output.

This financial modeling allows us to demonstrate a clear, bankable return on investment for the proposed customized battery energy storage system.

1.3 Advanced EMS Strategy & Control Logic

The Energy Management System (EMS) is the brain that executes the financial strategy. A generic EMS cannot adapt to complex tariffs or market signals. Our customization involves programming specific control logic for:

- Demand Charge Management: A sophisticated algorithm that predicts a facility’s 15-minute peak and dispatches the BESS with precision to “shave” the peak, directly reducing demand charges.

- Energy Arbitrage: Monitoring real-time electricity prices (where applicable) to automatically charge during low-cost hours and discharge during high-cost hours.

- Ancillary Services: For larger systems, programming the EMS to participate in grid services markets like frequency regulation, providing an additional revenue stream. This requires response times in milliseconds, a capability we verify during commissioning.

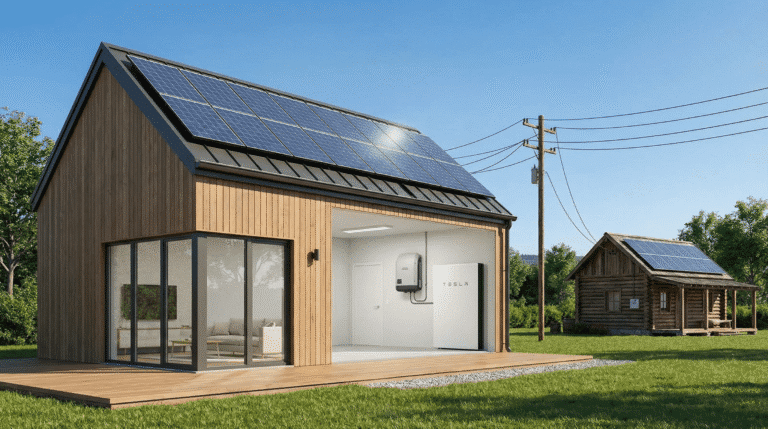

- Renewable Energy Firming: Smoothing the output of a co-located solar or wind asset to provide a predictable, dispatchable block of power.

1.4 Thermal Management and Fire Safety by Design

Safety and reliability are paramount. Our design philosophy for a customized battery energy storage system is rooted in exceeding minimum safety standards.

- Thermal Management: Battery health and safety are critically dependent on maintaining an optimal operating temperature (typically 20-30°C). We design thermal management systems (air-cooled for smaller systems, liquid-cooled for higher-density applications) to prevent thermal runaway. Our modeling accounts for the parasitic load of these systems.

- Multi-Level Fire Safety: Our systems are designed in compliance with NFPA 855 (Standard for the Installation of Stationary Energy Storage Systems) and are certified to UL 9540 (Standard for Energy Storage Systems and Equipment). This includes:

- Cell-Level: Using proven, safe chemistries like LFP.

- Module-Level: Integrated Battery Management Systems (BMS) monitor voltage and temperature for every cell block.

- Rack-Level: Smoke and gas detectors, and often an integrated fire suppression system (e.g., Novec 1230 or FM-200 clean agent).

- System-Level: Deflagration venting and physical separation as required by NFPA 855 to prevent propagation.

From the Field: A Case Study in Customization

Theoretical knowledge is insufficient without proven field experience. Here is a representative example of our process in action.

Client: A mid-sized cold storage and food processing facility in California.

The Challenge:

- Exorbitant electricity bills driven by high demand charges from refrigeration compressors and blast freezers.

- Frequent, momentary power quality issues from the local grid, causing sensitive equipment to trip and halting production lines.

- A corporate mandate to improve sustainability and reduce carbon footprint.

Our Process & Solution:

- Analysis: Our load profile analysis of their 15-minute interval data confirmed that over 40% of their monthly electricity bill was due to demand charges, concentrated in a 4-hour afternoon window.

- Modeling: Our LCOE modeling compared NMC and LFP battery chemistries. We selected a 1 MW / 2 MWh LFP-based customized battery energy storage system due to its superior cycle life and thermal stability, which provided a lower LCOE over the project’s 15-year lifespan.

- Design: We engineered a containerized solution with a liquid-cooled thermal management system to handle the high ambient temperatures. The system was designed to be fully compliant with UL 9540, and the installation plan was co-developed with the local fire marshal to meet NFPA 855 requirements.

- EMS Strategy: The EMS was programmed with a primary “peak shaving” algorithm and a secondary “power quality” mode. It continuously monitors the grid and can act as an uninterruptible power supply (UPS) for critical loads, switching in under 20 milliseconds.

Testing & Commissioning:

During the commissioning phase, our field engineers conducted a series of tests, including a full-power charge/discharge cycle to verify the round-trip efficiency and a simulated grid outage to confirm the seamless transition to backup power. All test records were documented and provided to the client.

Verified Results:

- Financial: A consistent 35% reduction in monthly demand charges.

- Operational: A 95% reduction in production stoppages caused by grid sags and swells.

- ROI: The project is on track for a 4.2-year return on investment, aided by California’s Self-Generation Incentive Program (SGIP).

Trust & Authority: Our Commitment to Verifiable Standards

- Core Certifications: Every major component in our systems is individually certified, and the complete, integrated system is certified to UL 9540. The batteries themselves are certified to UL 1973, and the inverters comply with IEEE 1547 for safe and reliable grid interconnection. We provide all certification documents as part of our project turnover package.

- Third-Party Validation & Industry Benchmarking: Our performance and financial models are benchmarked against independent industry data from sources like the National Renewable Energy Laboratory (NREL) and BloombergNEF (BNEF). For large-scale projects, we partner with third-party engineering firms like DNV to provide independent validation of our designs and performance guarantees.

- Partnerships: We maintain strategic partnerships with leading component manufacturers, ensuring we have access to Tier-1 technology and comprehensive support.

Conclusion and Professional Disclosures

Choosing a customized battery energy storage system is a significant technical and capital decision. The success of such a project is directly dependent on the rigor of the upfront engineering, the quality of the components, and the intelligence of the control software. A methodical, standards-compliant approach is the only way to guarantee safety, performance, and financial return. Our process is built on this foundation of engineering excellence.