The global transition to renewable energy hinges on the reliable and scalable deployment of energy storage systems. At the heart of this revolution lies the battery, but its journey from raw material to a fully commissioned project is fraught with peril. The intricate global network that constitutes the energy storage battery supply chain is vulnerable to a host of disruptions, creating significant challenges for developers, integrators, and investors. An unexpected break in this chain can trigger a domino effect of project delays, budget overruns, and even contractual penalties. The effective management of energy storage battery supply chain risk is no longer a competitive advantage; it is a fundamental requirement for survival and success in this booming industry.

The consequences of a fractured supply chain are severe. According to analysis from the International Energy Agency (IEA), significant supply chain bottlenecks in 2022 and 2023 led to increased costs and project timelines. Some reports indicated that these disruptions caused the average project delivery cycle for key components to extend by as much as 18%, a delay that can erode project profitability and stakeholder confidence. This article will provide a comprehensive framework to help you identify, assess, and actively mitigate energy storage battery supply chain risk, transforming vulnerability into a source of operational resilience and a cornerstone of sustainable growth.

Key Causes of Energy Storage Battery Supply Chain Disruptions

Understanding the origins of energy storage battery supply chain risk is the first step toward building a resilient strategy. These risks are multifaceted, stemming from market dynamics, geopolitical shifts, and unpredictable global events.

Raw Material Price Volatility

The prices of key raw materials for battery manufacturing—namely lithium, cobalt, and nickel—are notoriously volatile. This volatility is driven by a combination of speculative trading, demand surges from the electric vehicle (EV) and energy storage sectors, and concentrated mining operations in a few key geographies. A sudden price spike can decimate project budgets that were finalized months or even years in advance. For example, during the supply chain crunch of 2022, data from Shanghai Metals Market (SMM) showed that transportation blockades and logistics hurdles during COVID-19 lockdowns in Shanghai directly contributed to a surge in the price of lithium iron phosphate (LFP), a key battery cathode material, by over 30%. This highlights the acute financial energy storage battery supply chain risk associated with raw material markets.

International Logistics Instability

The majority of battery cells and components are manufactured in Asia and shipped globally. This reliance on maritime freight exposes the entire industry to significant logistical risks. Events like the Suez Canal blockage in 2021, ongoing port congestion in major hubs, and geopolitical conflicts impacting shipping lanes (such as tensions in the Red Sea) can cause cascading delays. These events not only extend lead times but also dramatically increase shipping costs, adding another layer of financial and operational energy storage battery supply chain risk.

Single-Supplier Dependency

For years, many companies prioritized cost savings by consolidating their procurement with a single, large-scale supplier. While this can yield economies of scale, it creates a critical point of failure. If that single supplier faces production issues, financial distress, quality control problems, or is impacted by a regional crisis, the buyer’s entire project pipeline can grind to a halt. This over-reliance is one of the most significant and self-inflicted forms of energy storage battery supply chain risk.

Policy and Regulatory Changes

Governments worldwide are increasingly viewing battery production as a matter of national security and economic strategy. This has led to a fluid and unpredictable policy landscape. Export controls on key materials (like China’s restrictions on graphite), sudden tariff adjustments, and local content requirements (such as those in the U.S. Inflation Reduction Act) can all disrupt established supply chains. Companies must constantly monitor and adapt to these policy shifts to mitigate the associated energy storage battery supply chain risk.

Natural Disasters and Extreme Weather

Climate change is exacerbating the frequency and intensity of extreme weather events. A typhoon in a key manufacturing region, a flood affecting a mining operation, or a wildfire disrupting a transportation corridor can halt production and logistics with no warning. These events represent a growing and unpredictable category of energy storage battery supply chain risk that requires robust contingency planning.

Identifying and Assessing Energy Storage Battery Supply Chain Risk

Proactive risk management begins with a systematic process of identification and evaluation. You cannot mitigate a risk you cannot see. A structured approach is essential for understanding the full spectrum of your energy storage battery supply chain risk.

Risk Classification and Priority Assessment

The first step is to map out your entire supply chain, from the mine to the project site. Then, classify potential risks into categories such as financial (price volatility), operational (production delays), logistical (shipping), geopolitical (tariffs), and environmental (natural disasters). Once categorized, each risk should be scored based on two factors:

Likelihood: How likely is this event to occur?

Impact: If it occurs, what is the severity of its effect on project cost, schedule, and quality?

This process creates a risk matrix that helps prioritize your focus, allowing you to allocate resources to managing the most critical threats to your energy storage battery supply chain.

Supplier Health Analysis

Your suppliers are your partners, but also a potential source of risk. A thorough and ongoing analysis of your suppliers’ health is crucial. This goes beyond their technical specifications and includes:

Financial Stability: Review their financial statements. Are they profitable? Do they have a healthy cash flow? A supplier on the brink of bankruptcy is a major red flag.

Production Capacity: Do they have sufficient capacity to meet your forecasted demand? Are they over-reliant on a few large customers, putting you at risk if demand from another buyer surges?

Performance Record: Analyze their historical on-time delivery rates, quality control data (e.g., cell failure rates), and responsiveness.

Supply Chain Visualization Tools and Digital Platforms

Modern supply chains are too complex to be managed on spreadsheets. Digital supply chain management platforms provide end-to-end visibility, allowing you to track shipments in real-time, monitor supplier inventory levels, and receive automated alerts about potential disruptions. These tools are invaluable for managing energy storage battery supply chain risk by replacing reactive problem-solving with proactive monitoring.

Risk Warning Indicators and Monitoring Systems

Establish a dashboard of Key Performance Indicators (KPIs) and leading indicators to serve as an early warning system. This could include:

Raw material price indices (Lithium, Cobalt, Nickel).

Global freight cost benchmarks (e.g., Freightos Baltic Index).

Supplier on-time delivery metrics.

Political risk scores for countries where suppliers are located.

Monitoring these indicators allows you to detect signs of trouble early, giving you more time to activate contingency plans and mitigate the potential impact of an emerging energy storage battery supply chain risk.

Core Strategies to Mitigate Energy Storage Battery Supply Chain Risk

Once risks are identified and assessed, the focus shifts to mitigation. The following strategies are essential for building a resilient and reliable energy storage battery supply chain.

Diversify Your Supplier Base: Dual Sourcing & Multi Sourcing

The single most effective strategy for reducing supplier-related energy storage battery supply chain risk is diversification.

Dual Sourcing: Engaging with two qualified suppliers for the same component. This creates healthy competition and provides an immediate backup if one supplier fails.

Multi Sourcing: Spreading your procurement across three or more suppliers, often in different geographic regions. This further insulates you from regional disruptions, be they political, logistical, or environmental.

According to a report from McKinsey & Company on supply chain resilience, companies that implemented strategic supplier diversification were able to reduce the impact of major supply disruptions by 30% to 50%. This demonstrates a clear return on investment for managing energy storage battery supply chain risk.

Implement a Strategic Safety Stock Policy

Safety stock is the extra inventory held as a buffer against demand forecast inaccuracies and lead time variability. While holding inventory has costs, the cost of a stockout and resulting project delay is often far greater. Calculating the right amount of safety stock involves analyzing historical lead time data, demand volatility, and your target service level. This buffer is a critical tool for absorbing minor shocks and ensuring that short-term logistical delays do not derail your project schedule, thus mitigating a key component of energy storage battery supply chain risk.

Utilize Long-Term Contracts and Price Locking Mechanisms

To combat raw material price volatility, engage in Long-Term Agreements (LTAs) with key suppliers. These contracts can lock in pricing for a set period (e.g., 1-3 years) or tie prices to an agreed-upon index with a predefined collar (a cap and a floor). This strategy provides budget certainty and insulates your projects from the wild swings of the spot market, directly addressing the financial aspect of energy storage battery supply chain risk.

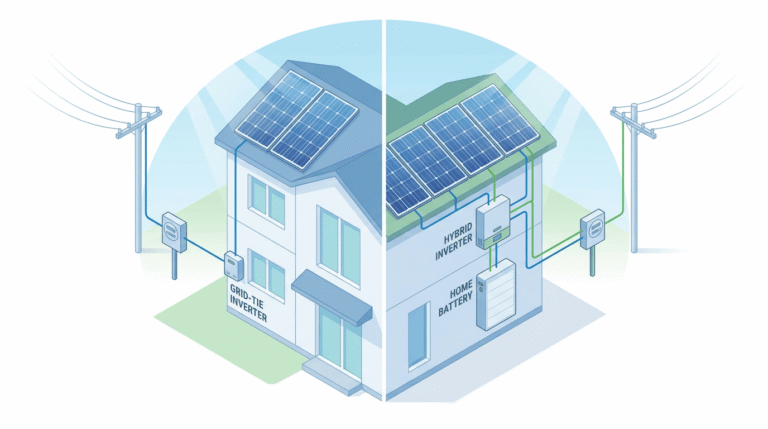

Embrace Localization and Regional Hubs

The trend of “nearshoring” or “onshoring” production is gaining momentum for good reason. Establishing manufacturing or assembly facilities closer to the end market, or creating regional warehousing hubs, can significantly reduce reliance on long, complex international shipping routes. This enhances supply chain elasticity, shortens lead times, and reduces vulnerability to global logistical chokepoints. This localization is a powerful tactic for de-risking your operations.

Develop an Emergency Logistics Plan

Hope for the best, but plan for the worst. Your standard logistics plan should rely on cost-effective sea freight, but you must have a pre-vetted emergency plan. This includes identified and pre-qualified air freight forwarders and land transportation partners who can be activated on short notice. While more expensive, having an air freight option can save a project from a multi-week delay for a critical component, making it a vital tool for controlling acute energy storage battery supply chain risk.

The Role of Digitalization and Intelligence in Risk Control

Technology is a powerful ally in the fight against supply chain volatility. Modern digital tools can enhance visibility, improve forecasting, and accelerate response times.

AI for Demand Prediction: Artificial intelligence and machine learning algorithms can analyze historical sales data, market trends, and even external factors (like weather patterns or policy announcements) to generate more accurate demand forecasts. Better forecasts lead to more efficient inventory management and a reduced energy storage battery supply chain risk of both stockouts and overstocking.

Blockchain for Supply Chain Transparency: Blockchain technology can create an immutable, transparent ledger that tracks components from their source to the final installation. This enhances traceability, helps verify the authenticity and ESG compliance of materials, and reduces the risk of counterfeit products entering your supply chain.

Cloud-Based Collaboration Platforms: These platforms provide a single source of truth for all stakeholders—your company, your suppliers, and your logistics partners. Real-time communication and data sharing enable faster decision-making and a more coordinated response when disruptions occur, which is essential for nimble energy storage battery supply chain risk management.

Smart Warehousing and Automated Logistics: Automated Storage and Retrieval Systems (ASRS), robotic picking, and GPS-enabled fleet management reduce human error, improve efficiency, and decrease the uncertainty associated with material handling and delivery.

Best Practices and Case Studies in the Industry

Leading companies are already putting these strategies into practice. For instance, many top-tier international energy storage integrators have aggressively moved from a single-supplier model with one primary cell manufacturer to a multi-supplier strategy. They now qualify and procure cells from at least two to three different top-tier manufacturers across different countries. This proactive management of energy storage battery supply chain risk has proven its worth.

Analysis from BloombergNEF (BNEF) has shown a clear correlation between supplier diversification and project execution success. Their data from 2023 indicated that energy storage companies with established dual-supplier systems experienced up to 20% lower rates of project delays attributed to battery shortages compared to their single-sourced competitors. This is a powerful testament to the financial and operational benefits of investing in a resilient supply chain. These companies have demonstrated that the upfront cost and effort of qualifying a second supplier are a small price to pay for the security and predictability it provides, proving the high ROI of diligent energy storage battery supply chain risk control.

Future Trends: Building a More Resilient Energy Storage Battery Supply Chain

The landscape of energy storage battery supply chain risk is constantly evolving. Looking ahead, several key trends will shape the industry’s approach to building more resilient and sustainable supply networks.

Supply Chain Localization and Regionalization: Spurred by government incentives like the U.S. Inflation Reduction Act and the EU’s Critical Raw Materials Act, a wave of investment is flowing into building out regional battery supply chains. This will reduce dependence on a single manufacturing region and strengthen energy security.

ESG and Green Supply Chain Initiatives: There is a growing demand for transparency and ethical sourcing. Companies will face increasing pressure from investors and customers to demonstrate that their supply chains are not only resilient but also environmentally sustainable and socially responsible. ESG compliance is becoming a core component of energy storage battery supply chain risk management.

Closed-Loop Supply Chains through Recycling: As the first generation of energy storage systems and EVs reaches the end of life, battery recycling will become a critical source of raw materials. Building a “circular” or “closed-loop” supply chain will reduce reliance on primary mining and create a more sustainable and predictable source of lithium, cobalt, and nickel.

Vertical Integration and Strategic Alliances: We are seeing a trend of companies moving to control more of their supply chain. This includes battery manufacturers acquiring mining assets and energy storage integrators forming joint ventures with cell producers. These strategic moves are designed to secure supply and directly manage energy storage battery supply chain risk.

Conclusion

The successful delivery of energy storage projects in the modern era is intrinsically linked to the resilience of the supply chain. The days of “set it and forget it” procurement are over. Proactive, strategic, and data-driven management of energy storage battery supply chain risk is now a critical business function.

By understanding the primary causes of disruption, implementing a systematic process for risk identification, and executing a multi-faceted mitigation strategy—centered on supplier diversification, strategic inventory, long-term contracts, and digitalization—your organization can navigate the inherent volatility of the global market. Building a resilient supply chain is an ongoing process of monitoring, adapting, and investing in the right partnerships and technologies. This commitment will not only protect your projects from delays and cost overruns but will also position your company as a reliable leader in the clean energy transition.

To stay ahead of the curve, we encourage you to subscribe to leading industry reports and consult with supply chain solution experts who can help you design and implement a risk management framework tailored to your specific business needs.